Biomedical Engineering Reference

In-Depth Information

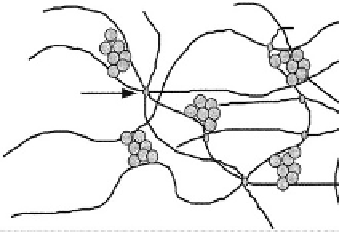

Cross-linking

site

PDMS

Silica

Fig. 3.2.3-2 Silicone elastomer matrix.

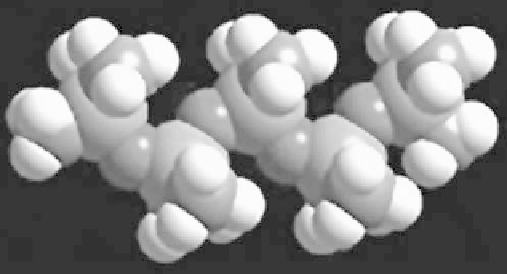

Fig. 3.2.3-3 Three-dimensional representation of dodeca-

methylpentasiloxane, Me

3

SiO-(SiMe

2

O)

3

SiMe

3

or MD

3

M.

(Courtesy S. Grigoras, Dow Corning.)

other medical materials such as PVC, which might con-

tain phthalate additives.

the polymer backbone does not allow a ''selective'' ex-

posure of the most organic or hydrophobic methyl

groups. Chain-to-chain interactions are low, and the

distance between adjacent chains is also greater in sili-

cones. Despite a very polar chain, silicones can be com-

pared to paraffin, with a low critical surface tension of

wetting (Owen, 1981).

The surface activity of silicones is evident in many

ways (Owen, 1981):

The polydimethylsiloxanes have a low surface

tension (20.4 mN/m) and are capable of wetting

most surfaces. With the methyl groups pointing to

the outside, this gives very hydrophobic films and

a surface with good release properties, particularly if

the film is cured after application. Silicone

surface tension is also in the most promising

range considered for biocompatible elastomers

(20-30 mN/m).

Silicones have a critical surface tension of wetting

(24 mN/m) higher than their own surface tension.

This means that silicones are capable of wetting

themselves, which promotes good film formation and

good surface covering.

Silicone organic copolymers can be prepared with

surfactant properties, with the silicone as the

hydrophobic part, e.g., in silicone glycols

copolymers.

The low intermolecular interactions in silicones have

other consequences (Owen, 1981):

Glass transition temperatures are very low, e.g.,

146 K for a polydimethylsiloxane compared to

200 K for polyisobutylene, the analog hydrocarbon.

The presence of a high free volume compared to

hydrocarbons explains the high solubility and high

diffusion coefficient of gas into silicones. Silicones

have a high permeability to oxygen, nitrogen, or

water vapor, even though liquid water is not capable

of wetting a silicone surface. As expected, silicone

compressibility is also high.

Physicochemical properties

Silicon

0

s position just under carbon in the periodic table

led to a belief in the existence of analog compounds

where silicon would replace carbon. Most of these analog

compounds do not exist, or behave very differently.

There are few similarities between Si-X bonds in sili-

cones and C-X bonds (Corey, 1989; Hardman, 1989;

Lane and Burns, 1996; Stark

et al.

, 1982).

Between any given element and Si, bond lengths are

longer than for C with this element. The lower electro-

negativity of silicon (

c

Si

z 1.80,

c

C

z 2.55) leads to

more polar bonds compared to carbon. This bond po-

larity also contributes to strong silicon bonding; for ex-

ample, the SiO bond is highly ionic and has large bond

energy. To some extent, these values explain the stability

of silicones. The SiO bond is highly resistant to homo-

lytic scission. On the other hand, heterolytic scissions are

easy, as demonstrated by the reequilibration reactions

occurring during polymerizations catalyzed by acids or

bases (see earlier discussion).

Silicones exhibit the unusual combination of an in-

organic chain similar to silicates and often associated with

high surface energy, but with side methyl groups that are

very organic and often associated with low surface energy

(Owen, 1981). The Si-O bonds are quite polar and

without protection would lead to strong intermolecular

interactions (Stark

et al.

, 1982). Yet, the methyl groups,

only weakly interacting with each other, shield the main

chain (see

Fig. 3.2.3-3

).

This is made easier by the high flexibility of the silox-

ane chain. Barriers to rotation are low and the siloxane

chain can adopt many configurations. Rotation energy

around a H

2

C-CH

2

bond in PE is 13.8 kJ/mol but only

3.3 kJ/mol around a Me

2

Si-O bond, corresponding to

a nearly free rotation. In general, the siloxane chain

adopts a configuration such that the chain exposes

a maximum number of methyl groups to the outside,

whereas in hydrocarbon polymers, the relative rigidity of