Biomedical Engineering Reference

In-Depth Information

shrinkage). Silicones with this cure system are therefore

not suitable for the fabrication of parts with precise

tolerances.

linked matrix. The strength of silicone polymers without

filler is generally unsatisfactory for most applications

(Noll, 1968). Like most other noncrystallizing synthetic

elastomers, the addition of reinforcing fillers reduces

silicone

0

s stickiness, increases its hardness and enhances

its mechanical strength. Fillers might also be employed to

affect other properties; for example, carbon black is

added for electrical conductivity, titanium dioxide im-

proves the dielectric constant, and barium sulfate in-

creases radiopacity. These and other materials are used to

pigment the otherwise colorless elastomer; however, care

must be taken to select only pigments suitable for the

processing temperatures and end-use application.

Generally, the most favorable reinforcement is

obtained using fumed silica, such as Cab-O-Sil, Aerosil,

or Wacker HDK. Fumed silica is produced by the hy-

drolysis of silicon tetrachloride vapor in a hydrogen flame:

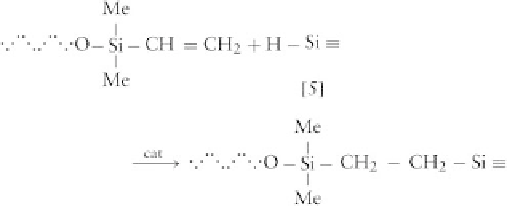

3. Cross-linking by Addition Use of an addition-cure

reaction for cross-linking can eliminate the shrinkage

problem mentioned above. In addition cure, cross-linking

is achieved by reacting vinyl endblocked polymers with

Si-H groups carried by a functional oligomer such as

described above [6]. A few polymers can be bonded to this

functional oligomer [6], as follows (Stark

et al.

, 1982):

1800

C

SiCl

4

þ

2H

2

þ

O

2

!

SiO

2

þ

4HCl

where h represents the remaining valences of the Si

in [6].

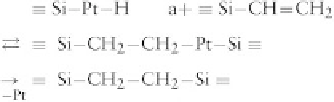

The addition occurs mainly on the terminal carbon and

is catalyzed by Pt or Rh metal complexes, preferably

as organometallic compounds to enhance their compati-

bility. The following mechanism has been proposed (oxi-

dative addition of the hSi to the Pt, H transfer to the

double bond, and reductive elimination of the product):

Unlike many naturally occurring forms of crystalline

silica, fumed silica is amorphous. The very small spheroid

silica particles (on the order of 10 nm diameter) fuse

irreversibly while still semimolten, creating aggregates.

When cool, these aggregates become physically entangled

to form agglomerates. Silica produced in this way pos-

sesses remarkably high surface area, 100 to 400 m

2

/g as

measured by the BET method developed by Brunauer,

Emmett, and Teller (Brunauer

et al.,

1938; Noll, 1968;

Cabot Corporation, 1990).

The incorporation of silica filler into silicone polymers

is called ''compounding.'' This is accomplished prior to

cross-linking, by mixing the silica into the silicone poly-

mers on a two-roll mill, in a twin-screw extruder, or in

a Z-blade mixer capable of processing materials with this

rheology.

Reinforcement occurs with polymer adsorption en-

couraged by the silica's large surface area and when hy-

droxyl groups on the filler's surface lead to hydrogen

bonds between the filler and the silicone polymer,

thereby contributing to the production of SRs with high

tensile strength and elongation capability (Lynch, 1978).

The addition of filler increases the polymer

0

s already

high viscosity. Chemical treatment of the silica filler with

silanes further enhances its incorporation in, and rein-

forcement of, the silicone elastomer, resulting in in-

creased material strength and tear resistance (Lane and

Burns, 1996) (

Fig. 3.2.3-2

).

Silicone elastomers for medical applications normally

utilize only fillers of fumed silica, and occasionally ap-

propriate pigments or barium sulfate. Because of their

low glass transition temperature, these compounded and

cured silicone materials are elastomeric at room and body

temperatures without the use of any plasticizers

where, to simplify, other Pt ligands and other Si sub-

stituents are omitted.

There are no by-products with this reaction. Molded

pieces made with silicone using this addition-cure

mechanism are very accurate (no shrinkage). However,

handling these two-part products (i.e., polymer and Pt

catalyst in one component, SiH oligomer in the other)

requires some precautions. The Pt in the complex is

easily bonded to electron-donating substances such as

amine or organosulfur compounds to form stable com-

plexes with these ''poisons,'' rendering the catalyst in-

active and inhibiting the cure.

The preferred cure system can vary by application. For

example, silicone-to-silicone medical adhesives use

acetoxy cure (condensation cross-linking), and platinum

cure (cross-linking by addition) is used for precise sili-

cone parts with no by-products.

4. Elastomer Filler In addition to the silicone poly-

mers described above, the majority of silicone elastomers

incorporate ''filler.'' Besides acting as a material extender,

as the name implies, filler acts to reinforce the cross-

d

unlike