Biomedical Engineering Reference

In-Depth Information

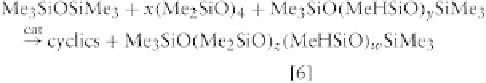

existing polymers to obtain a polydimethyl-methylhy-

drogenosiloxane, MD

z

D

H

w

M.

Silicone elastomers

Silicone polymers can be easily transformed into a three-

dimensional network by way of a cross-linking reaction,

which allows the formation of chemical bonds between

adjacent chains. The majority of silicone elastomers are

cross-linked according to one of the following three

reactions.

Additional functional groups can be attached to this

polymer using an addition reaction.

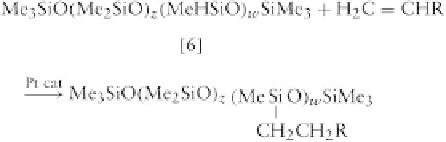

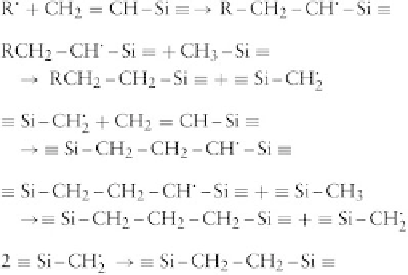

1. Cross-Linking with Radicals Efficient cross-linking

with radicals is only achieved when some vinyl groups are

present on the polymer chains. The following mechanism

has been proposed for the cross-linking reaction associ-

ated with radicals generated from an organic peroxide

(Stark

et al.

, 1982):

The polymers shown are all linear or cyclic, comprising

difunctional units, D. In addition to these, branched

polymers or resins can be prepared if, during hydrolysis,

a certain amount of T or Q units are included, which will

allow molecular expansion, in three or four directions, as

opposed to just two. For example, consider the hydro-

lysis of methyltrichlorosilane in the presence of trime-

thylchlorosilane, which leads to a branched polymer as

shown next:

where h represents two methyl groups and the rest of

the polymer chain.

This reaction has been used for high-consistency sili-

cone rubbers (HCRs) such as those used in extrusion or

injection molding, as well as those that are cross-linked at

elevated temperatures. The peroxide is added before

processing. During cure, some precautions are needed to

avoid the formation of voids by the peroxide

0

s volatile

residues. Postcure may also be necessary to remove these

volatiles, which can catalyze depolymerization at high

temperatures.

2. Cross-Linking by Condensation Although mostly

used in silicone caulks and sealants for the construction

industry and do-it-yourselfer, this method has also

found utility for medical devices as silicone adhesives

facilitating the adherence of materials to silicone elas-

tomers, as an encapsulant and as sealants such as

around the connection of a pacemaker lead to the pulse

generator (

Fig. 3.2.3-1

shows Silastic Medical Adhe-

sive, type A).

These products are ready to apply and require no

mixing. Cross-linking starts when the product is

squeezed from the cartridge or tube and comes into

contact with moisture, typically from humidity in the

ambient air. These materials are formulated from a re-

active polymer prepared from a hydroxy end-blocked

polydimethylsiloxane

The resulting polymer can be described as ((Me

3

SiO

1/2

)

x

(MeSiO

3/2

)

y

or M

x

T

y

, using shorthand notation. The

formation of three silanols on the MeSiCl

3

by hydrolysis

yields a three-dimensional structure or resin, rather than

a linear polymer. The average molecular weight depends

upon the number of M units that come from the trime-

thylchlorosilane, which limits the growth of the resin

molecule. Most of these resins are prepared in a solvent

and usually contain some residual hydroxyl groups. These

could subsequently be used to cross-link the resin and

form a continuous network.

and

a

large

excess

of

methyl-

triacetoxysilane.