Biomedical Engineering Reference

In-Depth Information

and the scaffold can dramatically increase the cell adhesion area.

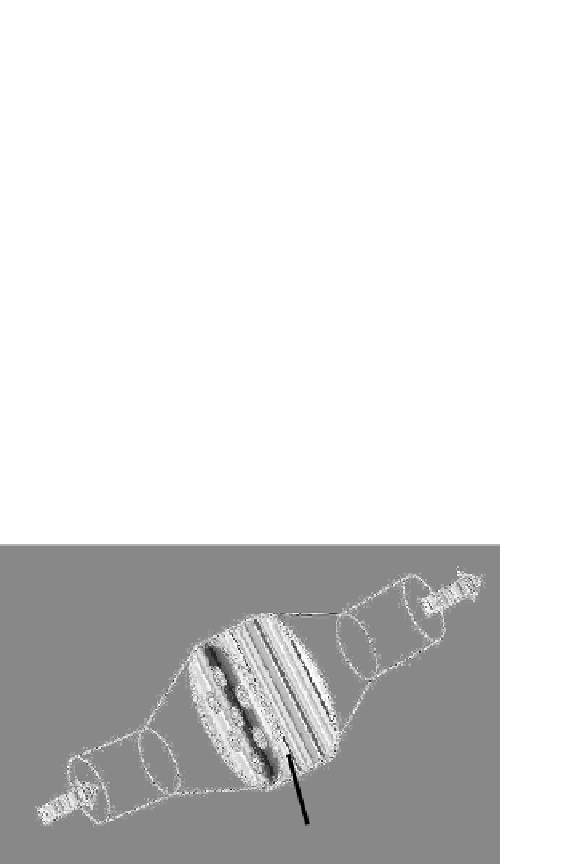

Therefore, a perfusion bioreactor should be designed for installing

a lot of microchannels for supplying nutrients and oxygen and

removing waste products as real capillaries in 3D biodegradable

polymer having high-density cultured cells [22, 23]. Radisic et al.

fabricated microchannels in cylindrical biodegradable (polylactic

acid), and myocardial cells were seeded into the microchannels

with perfusion (Fig. 6e.3). Compared with cells cultured in a stirring

culture, the viability of culture cells expressing cardiomyocyte-

specific markers in the microchannels was found to be improved,

indicating that constructed 3D myocardial tissue can be prepared

with a perfusion culture method using a scaffold with a capillary

network [24-26]. Bioreactor systems give a biomimic circumstance

to supply oxygen in an in vivo-mimicking manner for overcoming

diffusion limitations found in conventional culture systems.

However, in these methods, the geometry of the cell location was

totally different from those in vivo situations, such as cell density

and capillary construct.

Biodegradable polymer with microchannels

Figure 6e.3

Perfusion bioreactor.

6e.5

In vivo Perfusion Bioreactor and in vivo

Tissue Culture

A vascular network having 10 μm diameter capillaries is found

to run among cells in the complex structure of real living tissue.