Environmental Engineering Reference

In-Depth Information

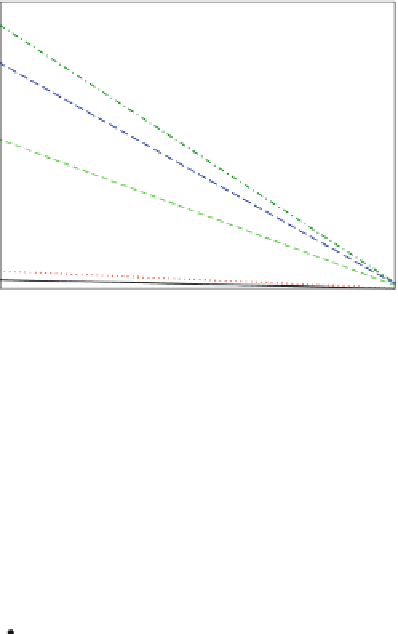

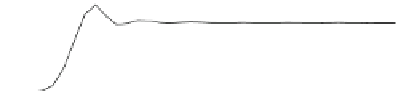

Fig. 14

Velocity profile for

the linear Couette flow

simulations for different wall

velocities (shear rate). The

velocity is scaled with the

dynamic scale of a polymer

melt of the same density as

the brush

D

w

D

5*ˁ

melt

v

w

=0.06

v

w

=0.12

v

w

=1.00

v

w

=1.50

v

w

=1.75

12

*

=13.40

ˁ

10

8

R

e

,where

D

w

is the channel width,

D

the diffusion coefficient of

the equivalent polymer melt

and

R

e

its end-to-end

distance. The

open squares

show the density profile of

the same system. It should be

noted that it is highly

independent of the flow

conditions. Adapted from

Pastorino et al. (

2009

)

/

6

4

2

0

3

4

2.5

3.5

4.5

5

12

*

=35.10

ˁ

10

8

6

4

2

0

4

3.5

4.5

5

z/R

e

In these examples, the Couette (linear) flow is established by moving the walls

of the polymer-coated channel at constant and opposite velocity. This builds up, at

stationary regime, a linear velocity profile in the channel with 0 velocity exactly at

the center of the channel.

A typical simulation is shown in the inset of Fig.

13

. The Figure shows a density

profile with the two species in the system: a polymeric liquid of ten-bead chains

(gray) which is confined between two layers of end-grafted polymers, a polymer

brush (red). The densities show the brush-liquid interfaces clearly defined. The liquid

is not able to enter in the brush layer, even when all the interactions are attractive, due

to entropic effects (Pastorino et al.

2007

,

2009

). This corresponds to the well-known

case of autophobicity (Pastorino et al.

2006

). The brush thickness depends on the

grafting density (number of chains per unit area grafted at the wall). This system can

be studied in equilibrium and also under flow.

The velocity profiles obtained as a result of moving the wall at constant and oppo-

site velocity are shown in Fig.

14

. The linear velocity profiles are clearly observed

for two different grafting densities in the brush (upper and lower panels). The density

Search WWH ::

Custom Search