Chemistry Reference

In-Depth Information

Chapter 5

Electrospinning of Chitosan (CHT)

Z. Moridi Mahdieh, V. Mottaghitalab, N. Piri, and A.K. Haghi

INTRODUCTION

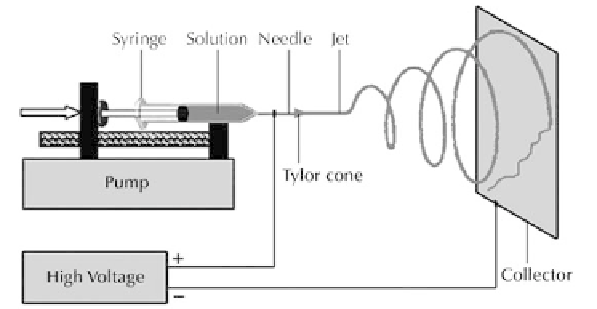

Over the recent decades, scientists interested to creation of polymer nanofibers due to

their potential in many engineering and medical applications [1]. According to various

outstanding properties such as very small fiber diameters, large surface area per mass

ratio, high porosity along with small pore sizes and flexibility, electrospun nanofiber

mats have found numerous applications in diverse areas. For example in biomedical

field nanofibers plays a substantial role in tissue engineering [2], drug delivery [3], and

wound dressing [4]. Electrospinning is a sophisticated and efficient method by which

fibers produces with diameters in nanometer scale entitled as nanofibers. In electrospin-

ning process, a strong electric field is applied on a droplet of polymer solution (or melt)

held by its surface tension at the tip of a syringe needle (or a capillary tube). As a result,

the pendent drop will become highly electrified and the induced charges distributes

over its surface. Increasing the intensity of electric field, the surface of the liquid drop

will be distorted to a conical shape known as the Taylor cone [5]. Once the electric field

strength exceeds a threshold value, the repulsive electric force dominates the surface

tension of the liquid and a stable jet emerges from the cone tip. The charged jet then ac-

celerates toward the target and rapidly thins and dries because of elongation and solvent

evaporation. As the jet diameter decreases, the surface charge density increases and the

resulting high repulsive forces split the jet to smaller jets. This phenomenon may take

place several times leading to many small jets. Ultimately, solidification is carried out

and fibers deposits on the surface of the collector as a randomly oriented nonwoven mat

[6-7]. Figure 5.1 shows a schematic illustration of electrospinning setup.

Figure 5.1.

A typical image of electrospinning process [8].

Search WWH ::

Custom Search