Chemistry Reference

In-Depth Information

macroscopic structure in the form of films, hydrogels, and fibers [157]. The CNT/

CS dispersions in acetic acid were spun into an ethanol: NaOH coagulation solution

bath. They were demonstrated increasing mechanical properties of wet spun fibers by

improving dispersion [158].

Electrospinning

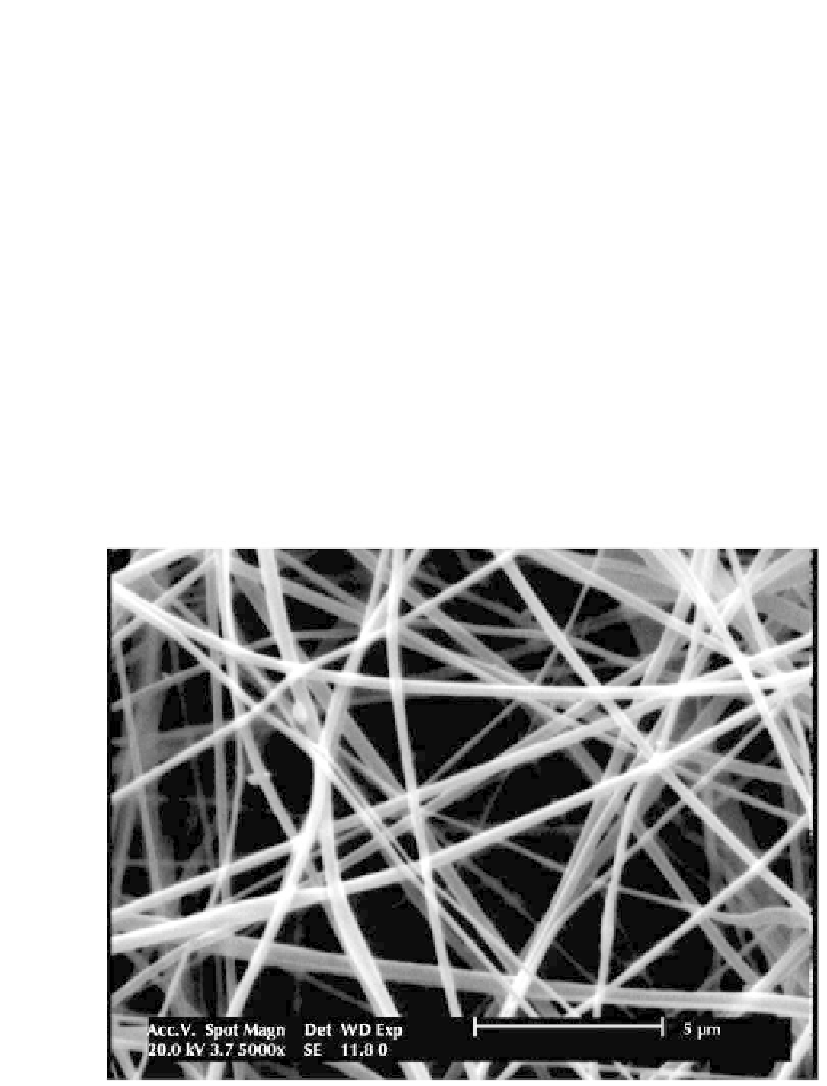

In our recent work, the CS/MWNTs composite nanofiber were fabricated using elec-

trospinning. In our experimental researches, different solvents including acetic acid

1-90%, formic acid, and TFA/DCM were tested for the electrospinning of CS/CNT.

No jet was seen upon applying the high voltage even above 25 kV by using of acetic

acid 1-30% and formic acid as the solvent for CS/CNT. When the acetic acid 30-90%,

used as the solvent, beads were deposited on the collector. Therefore, under these con-

ditions, nanofibers were not formed.

The TFA/DCM (70:30) solvent was only solvent that resulted for electrospinnabil-

ity of CS/CNT. The scanning electron microscopic (Fig. 7.7 showed the homogenous

fi bers with an average diameter of 455 nm (306-672) were prepared with CS/CNT

dispersion in TFA/DCM 70:30. These nanofi bers have a potential for biomedical

applications.

Figure 7.7.

SEM micrograghs of electrospun fibers of CS/MWNT at chitosan concentration of 10

wt%, 24 kV, 5 cm, TFA/DCM: 70/30 (0.06% wt MWNT).

Search WWH ::

Custom Search