Biomedical Engineering Reference

In-Depth Information

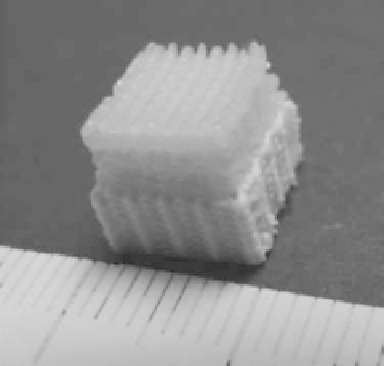

FIGURE 4.15

Photograph of a biphasic scaffold with separate layers for osteochondral tissue engineering.

The bottom layers were plotted from a CPC-alginate mixture for treatment of the bony part

and the top layers consist of alginate for the chondral part of the defect.

4.4 3D Plotting of Silicon-Based Bioceramic Scaffolds

Silicon-based bioceramics and scaffolds play an increasing role in bone tis-

sue engineering because silicon is one of the important trace elements in

human bone and is reported to stimulate new bone growth (Mertz 1981;

Pietak et al. 2007). Conventional methods for fabrication of porous silicon-

based bioceramic scaffolds are particle leaching and polyurethane template

sintering (Wu et al. 2010). As previously discussed, the drawbacks of these

methods do not only include poor control of pore parameters but also weak

mechanical properties of these scaffolds. Therefore, our intention was to

fabricate silicon-based scaffolds with designed pores with the application of

rapid prototyping.

In our work, two types of silicon-based scaffolds were printed by using

pastes containing either β-CaSiO

3

or mesoporous Ca-Si-P bioglass. β-CaSiO

3

is one of the most important silicon compounds used as bone replacement

material because β-CaSiO

3

degrades faster and has been demonstrated to

stimulate bone formation

in vivo

better than β-tricalcium phosphate (β-TCP)

(Xu et al. 2008). Ca-Si-P bioglass with regular nanochannels and high specific

surface area is a bioactive material. Numerous reports have demonstrated

that Ca-Si-P bioglass not only is an excellent drug delivery system but also

a potential candidate for bone repair (Lόpez-Noriega et al. 2006). β-CaSiO

3

powder was synthesized by a chemical precipitation method (Wu et al.

2012). Ca-Si-P bioglass was synthesized by a sol-gel and assembly technique

according to a published protocol (Wu et al. 2010). The product was ground

Search WWH ::

Custom Search