Biomedical Engineering Reference

In-Depth Information

80

60

40

20

Alginate

Mixed

CPC

0

0

50

100

150

200

250

300

350

400

Time (hour)

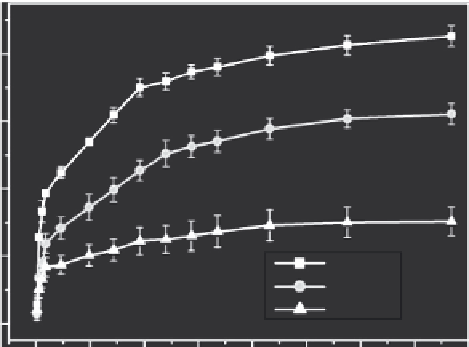

FIGURE 4.14

BSA release from plotted scaffolds in SBF at 37°C over a period of 16 days.

released from the pure alginate scaffolds because of the high nanoporosity

of the hydrogel and quick degradation of alginate scaffolds as well as the low

protein binding capacity of alginate in general. Again, for the mixed algi-

nate-CPC scaffolds an intermediate release profile was detected. It can be

speculated that the release of proteins from biphasic CPC-alginate scaffolds

can be controlled by altering the loading amount of BSA in CPC and alginate

strands (Figure 4.14).

Our data demonstrate the beneficial effect of the combination of ceram-

ics and polymers by alternate extrusion that result in biphasic scaffolds.

Especially with respect to the mechanical properties the performance of the

biphasic CPC-alginate composite scaffolds exceed that of those fabricated

by 3D plotting of a mixed paste of CPC and alginate. In addition, the bipha-

sic CPC-alginate scaffolds performed better in first cell culture experiments

compared to the mixed ones.

Furthermore, by using the 3D plotting technique and a device that allows

the utilization of more than one pasty material for one scaffold, an upgraded

biphasic scaffold with separate layers suitable for repair of defects at tissue

interfaces can be developed (Figure 4.15). Such a complex scaffold could

be designed, for example, for an osteochondral defect, by combining an

organic/inorganic composite layer to fill the bony part of the lesion and a

non-mineralized organic layer for the repair of the chondral part. To ensure

that both layers are tightly connected to each other, they have to be plotted

simultaneously and some of the strands of the organic phase have to pen-

etrate the other (composite) layers realizing a mechanically stable interlock-

ing of both materials.

Search WWH ::

Custom Search