Biomedical Engineering Reference

In-Depth Information

(a)

400

300

200

100

0

No Sintering

Sintering (1250°C-3h)

(c)

(b)

10 µm

10 µm

FIGURE 4.8

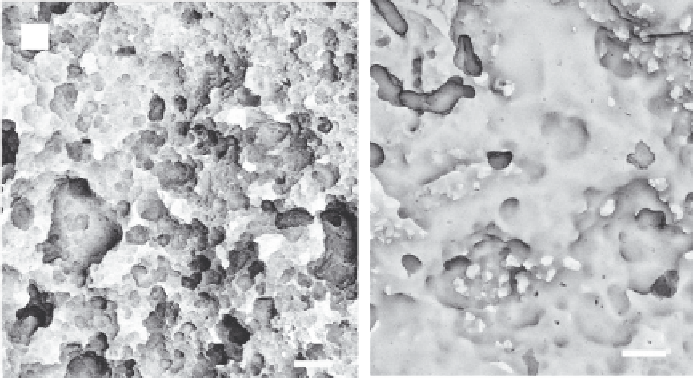

High-magnification SEM images showing the microstructures of ( b) nonsintered and (c) sintered

(at 1250°C and 3 h) CPC scaffolds and (a) the Young's modulus of the two types of scaffolds.

Most porous calcium phosphate bioceramic scaffolds are produced or

at least posttreated at high temperatures since the high crystallinity and

increased density induced by the sintering strongly enhance the mechani-

cal properties. On the other hand, the biodegradability of such materials

is limited (Bohner 2000) and the incorporation of drugs, growth factors,

or autologous components is possible only after fabrication of the scaffold.

CPC does not require postsintering to achieve stable structures and it can

set and harden under mild conditions, according to the requirements in

water or a humidified environment. In addition, due to free spaces between

precipitated crystals, calcium phosphate bone cements exhibit a high intrin-

sic microporosity and the resultant large surface area is beneficial for drug

loading (Espanol et al. 2009). The nanocrystalline structure of CPC finally

Search WWH ::

Custom Search