Biomedical Engineering Reference

In-Depth Information

80

70

60

50

40

30

20

3.0

2.5

2.0

1.5

1.0

0.5

0.0

10

46

48

50

52

54 56

Porosity (%)

58

60

62 64

46

48

50

52

54 56

Porosity (%)

58

60

62

64

(a)

(b)

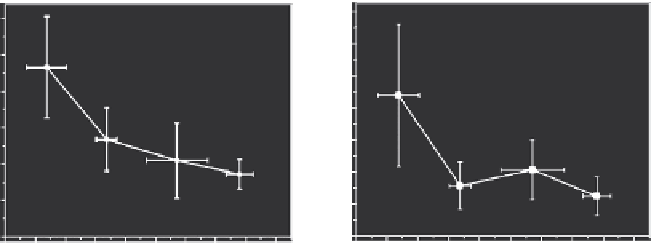

FIGURE 4.7

(a) Compressive strength and (b) modulus of plotted CPC scaffolds with different porosity (n =

5). Scaffolds with a size of 10 mm × 10 mm × 10 mm were tested by using an Instron 5566 testing

machine with a 10 kN load cell and a constant rate of 1 mm/min.

material but are also strongly affected by the pore parameters including size,

morphology, distribution, and orientation. In case of scaffolds fabricated by

RP technologies, the influence of macroporosity and scaffold architecture,

predefined by the CAD data set, on mechanical strength has been clearly

demonstrated by several studies (Hutmacher et al. 2001; Zein et al. 2002;

Sobral et al. 2011). The mechanical properties of the plotted CPC scaffolds

are, to a certain extent, adaptable by design and changing the pore param-

eters. Generally, a uniform and continuous pore structure and orientation

improves the mechanical strength (Wu et al. 2008, 2011) and in this respect,

scaffold fabrication applying the technique of 3D plotting has an advantage

over other conventional methods.

The 3D plotted CPC scaffolds set in water were mechanically weaker than

those sintered at high temperature. We studied the modulus of the plot-

ted CPC scaffolds with and without sintering and found that the plotted

CPC scaffolds produced with an additional sintering step (1250°C for 3 h)

acquired a modulus of about 330 MPa, which is nearly seven times higher

than that of samples with the same geometry produced without sintering

(Figure 4.8a). As apparent from SEM investigations (Figure 4.8b,c), high tem-

perature sintering results in highly crystalline materials with, compared to

cements, bigger particles that are connected to each other by sinter necks.

This structural feature is accompanied by a higher mechanical strength. In

contrast, CPC consists of smaller, mostly nanocrystalline particles that were

formed and became entangled during the precipitation reaction providing

mechanical rigidity (Bohner 2000). Accordingly, the SEM image shown in

Figure 4.8a reveals that the surface of the nonsintered CPC strands is highly

porous with plenty of small particles that seem to be bonded weaker com-

pared to the more dense counterparts produced by sintering.

Search WWH ::

Custom Search