Biomedical Engineering Reference

In-Depth Information

TABLE 7.4

Apatite Formation Time on Bioceramic Coatings in SBFs

Apatite

Formation(ks)

CoatingMethod

PhaseofCoating

SBF

Reference

Thermal CVD

HAp

Hanks' solution

21.6

(27)

Thermal CVD

α-TCP

Hanks' solution

1209.6

(27)

Thermal CVD

CaTiO

3

complicated surface

Hanks' solution

259.2

(68)

Thermal CVD

CaTiO

3

smooth surface

Hanks' solution

3628.8

(68)

Laser CVD

Hanks' solution

259.2

(28)

HAp, β-TCP

Plasma spraying

HAp

Kokubo solution

86.4

(69)

Sol-gel

HAp + TiO

2

Kokubo solution

691.2

(70)

formation in Kokubo solution.

(71)

In CVD, a spatial gap suitable to apatite formation can be

introduced by controlling the surface morphology of the bioceramic coatings.

The relationship between the crystallographic orientation of HAp coatings prepared by

CVD and apatite formation in SBF has been studied. Apatite formation on an HAp coating

oriented to the

c

-axis (i.e., the 〈002〉 direction) in Hanks' solution was faster than that oriented

to other directions. Preferential apatite formation on the

c

-face of HAp has been reported in

the immersion test of a highly oriented HAp sintered body in Kokubo solution.

(72)

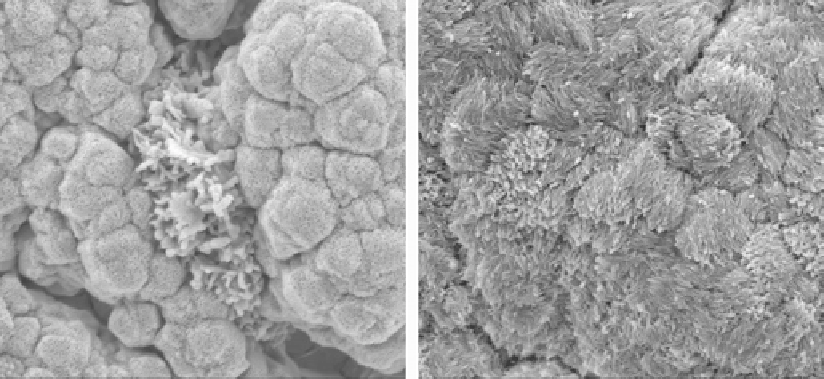

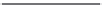

Figure 7.30a

and b show the surface morphology of HAp coatings prepared by laser CVD oriented to

the

a

-axis (i.e., the 〈300〉 direction) after immersion in Hanks' solution for 259.2 and 604.8

ks, respectively. Although the apatite formation rate on the (300)-oriented HAp coating was

not high, apatite formation was observed at hollow places 259.2 ks after immersion and the

whole surface was covered with needlelike apatite crystallites 604.8 ks after immersion.

These results suggest that the hollow places and (002) preferred orientation in bioceramic

coatings enhance the apatite formation in SBF.

(a)

(b)

FIGURE 7.29

Surface morphology of HAp coatings prepared by thermal CVD after immersion in Hanks' solution for (a) 3.6 ks

and (b) 21.6 ks.

Search WWH ::

Custom Search