Biomedical Engineering Reference

In-Depth Information

feed rate, 2) exponential feed rate, and 3) exponential and then constant feed rate strategy.

The constant rate is the easiest control strategy and commonly used. The exponential feed

operation can be at any rate, up to the maximum rate in the exponential growth phase of

a batch growth. This is the case that closely resembles a chemostat operation (Chapter 12).

The exponential feed requires the feed rate to increase exponentially and can be demanding

for the feeding system. One way to alleviate the difficulty is to feed exponentially first to

increase the feed rate at an acceptable level and then maintain a constant feed. Usually,

maximum growth rate is not optimal as by-product production can be high, which is the

main drawback of batch fermentation.

During fed-batch operations, besides the substrate and product concentrations change

with time in the reactor, the total reaction mixture (volume) also changes with time. There-

fore, comparing to common desired batch and/or flow reactors, there are at least three

balance equations needing to be dealt with before the problem can be solved.

13.1. DESIGN EQUATIONS

Evaluation of batch reactor performance relies on extensive mass and energy balances. We

have learned in Chapter 3 how mass and energy balances work. Let us apply the mass and

energy balances in this section for a fed-batch reactor. The control volume is shown in

Fig. 13.3

.

13.1.1. Overall Mass Balance in the Reactor

d

ðrVÞ

d

t

r

F

Q 0 þ 0 ¼

(13.1)

Q

S

F

X

F

=

0

V

,

S

,

X, P

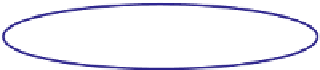

FIGURE 13.3

A schematic of fed-batch reactor. The feed volumetric rate is

Q

, which is sterile

X

F

¼

0 and

contains the substrate at a concentration of

S

F

. The volume of the media in the batch reactor is

V

, with the biomass

concentration being

X

, substrate concentration being

S

and a cellular product concentration of

P

.

Search WWH ::

Custom Search