Biomedical Engineering Reference

In-Depth Information

the fermentation process. In fact, the feed can be modified accordingly to the different phases

of the microbial growth, as a consequence of physiological alterations that the cells undergo

upon transfer through eventual consecutive stages of the fed-batch cultivation.

Usually, a fed-batch starts in batch mode and after a certain biomass concentration or

substrate consumption, the fermentor is fed with the limiting substrate solution. However,

that approach does not need to be the absolute rule. Some cases happen in which the rate

of production of a certain product is limited not only by the substrate but also by a primary

product, associated with the growth of the microorganism. That is the case of streptokinase

formation. Streptokinase is a vital and effective drug for the treatment of myocardinal infec-

tion that is produced commercially by mainly natural or mutated strains of streptococci. The

specific growth rate is inhibited by the substrate and by lactic acid. A near-optimal feed

policy based on a chemotaxis algorithm has been established that defines an initial

decreasing feeding phase, followed by a batch fermentation with no more added substrate

in the medium. The starting point was the data provided by the batch fermentations and

the feed was defined as being a polynomial function of time. By iterative calculations and

having the maximum allowable volume of the fermentor as time limits, a feed strategy

was defined yielding a 12% increase in streptokinase activity over batch fermentations.

This type of approach has also been suggested for ethanol production by

S. cerevisiae

that

follows the same kinetics.

Finally, the feed can be continuous, can be provided in pulses, as a shot feeding, single or

multisubstrate, increasing linearly, be exponential or constant with time. The design of the

feed solution may follow a conventional approach

in which the nutrients are more concen-

trated as compared with the growing medium in the fermentor

e

or follows a quantitative

design in such a way that depletion or accumulation of nutrients can be avoided or reduced.

Substrate limitation offers the possibility to control the reaction rates to avoid technolog-

ical limitations connected to the cooling of the reactor and oxygen transfer. Substrate limi-

tation also allows the metabolic control, to avoid osmotic effects, catabolite repression, and

overflowmetabolism of side products.

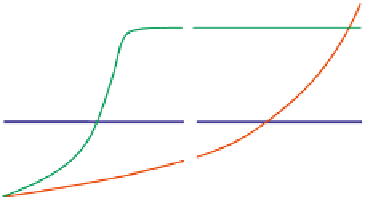

Fig. 13.2

shows the feed rate as a function of time for

fed-batch operations. There are many ways of implement control on the fermentation via

feed and at least three different operation strategies for fed-batch are useful: 1) constant

e

3

1

2

0

0

t

E

t,

minutes

FIGURE 13.2

A schematic commonly employed feed rate strategies for a fed-batch reactor operation.

1) Constant feed rate, this is the easiest one to implement and control; 2) exponential feed rate; and 3) exponential

e

constant feed strategy.

Search WWH ::

Custom Search