Biomedical Engineering Reference

In-Depth Information

8

0.8

7

0.7

6

0.6

5

0.5

4

0.4

3

0.3

2

0.2

1

0.1

0

0.0

0

2

4

6

8

10

12

14

16

18

20

Time, h

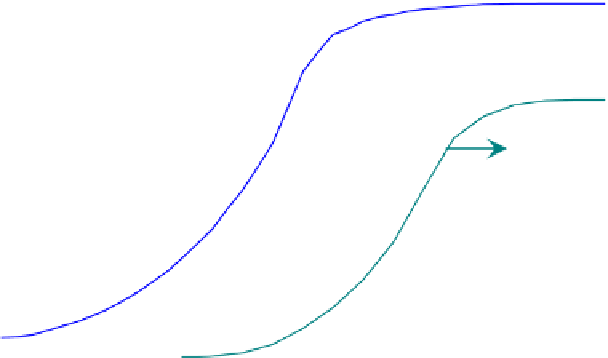

FIGURE E12-3.1

Biomass concentration and the concentration of a secondary metabolite in a batch culture.

Mass balance of the secondary metabolite

P

over the

i

th chemostat at steady state gives:

QP

i1

QP

i

þ r

Pi

V

i

¼ 0

(E12-3.3)

Dividing through by

V

i

, we obtain

r

Pi

¼ D

i

ðP

i

P

i1

Þ (E12-3.4)

Eqns (E12-3.4)

and

(E12-3.2)

are similar, in that the rate of formation of the secondary metab-

olite is a straight line on the rate vs concentration plane passing through the feed point

(

P

¼

P

i

1

,

r

P

¼

0) with a slope of D

i

, intercepts with the fermentation rate curve at (

P

¼

P

i

,

r

P

¼

r

P

i

). Therefore, if the rate functions are known, one can solve the problem easily (as

we have been doing). Alternatively, we can solve the problem graphically based on the prop-

erty as mentioned.

Therefore, to solve the problem, we must produce the rate curves. For the batch data, there

were minimum measurements available: only the concentrations of biomass and product

change with time. Fortunately, this is enough to produce the rate curves. In batch operations,

mass balance yields

d

C

j

d

r

j

¼

(E12-3.5)

t

Thus, the rate of production can be obtained by differentiating the concentration curve (either

measure the slopes of tangential lines or via central difference). These curves are shown in

Figs E12-3.2 and E12-3.3

. The quality or smoothness of the curves in

Figs E12-3.2

and

E12-3.3

is noticeably poor, which is due to the differentiation of data. The error in the data

is magnified and distorted because of the differentiation (see Chapter 7).

Search WWH ::

Custom Search