Biomedical Engineering Reference

In-Depth Information

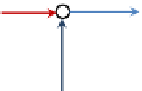

(a)

F

A0

Q

A

C

A0

Q

Q

,

f

Ae

C

B0

C

Ae

,

C

Be

F

B0

Q

B

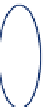

(b)

F

B0

Q

B

C

B0

Q

0

Q

,

f

Ae

C

A

C

Be

,

C

A

A0

Q

A

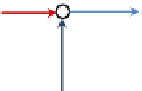

(c)

F

A0

Q

A

C

A0

Q

0

Q

,

f

Ae

C

B

C

Ae

,

C

B

B0

Q

B

FIGURE 5.16

Selected feed schemes for a two reactant systems in PFR. (a) Feeding both A and B at the beginning.

(b) Feeding B at the beginning, while maintaining

C

A

constant by adjusting the feed distributed along the reactor.

(c) Feeding A at the beginning, while maintaining

C

B

constant by adjusting the feed distributed along the reactor.

For 90% conversion of A, find the concentration of R in the product stream as a function

of the reaction rate constants. Equal volumetric flow rates of the A and of the B streams

are fed to the reactor, and each stream has a concentration of 20 mol/L of the said reactant.

Therateparametersare:

k

1

¼

0.1 mol

1/2

$

L

1/2

$

min

1

;

k

2

¼

0.2 min

1

;

K

A

¼

10 mol

1

$

L;

5mol

1/2

$

L

1/2

. The flow in the reactor follows:

and

K

B

¼

1. PFR;

2. CSTR;

3. The best of the three PFR contacting (feeding) schemes in

Fig. 5.16

.

Solution. As a warning, be careful to get the concentrations and flow rates right when you

mix the streams. To begin with, we find the differential selectivity of the desired product

d

F

A

j

due to the formation of R

d

F

A

j

total

r

1

A

k

1

C

A

k

1

C

A

þ k

2

C

1=2

s

R

=

A

¼

¼

r

1

A

þ r

2

A

¼

(E5-7.3)

B

One can solve the problem by performing mole balances on each species and solve the differ-

ential equations using an automatic integrator. We can also do it more illustrative by using the

differential selectivity as defined by

Eqn (E5-7.3)

. This is the approach we will be taking here.

1. PFR. Referring to

Fig. 5.16

a, noting that the starting concentration of each reactant in

the combined feed is

C

A0

¼

C

B0

¼

20 mol/L

O

2

¼

10 mol/L. Based on the stoichiometry,

Search WWH ::

Custom Search