Chemistry Reference

In-Depth Information

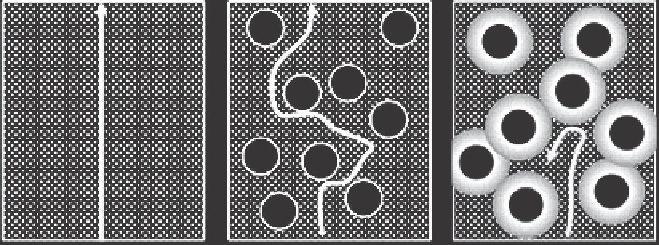

(a)

(b)

(c)

Figure 9.1:

Permeability of a small molecule through PDMS as illustrated for the unfilled polymer

(a), a nonpermeable filler decreasing the permeability of the PDMS by requiring a more

tortuous route around the filler particles (b), and a filler that interacts so strongly with

the PDMS that the PDMS segments close to the filler surface are so restricted that they

are frequently called “bound rubber” (c).

406- 409

surface properties,

64

thermomechanical behavior,

65

optical properties,

66

and

degree of cross linking from the silica-based nanoparticles.

67

Fluorescence

analysis is also possible in silica-PDMS nanocomposites in which the poly-

mer is labeled with dansyl chromophores

68

or lanthanide complexes.

69-71

A variety of other nanoparticles have been formed by such in situ sol-gel

reactions. Examples are the oxides of titanium,

72-79

aluminum,

72,

73

tanta-

lum,

72,

80

zirconium,

73,

77

niobium,

80

and vanadium.

81

Some nanocompos-

ites of this type have also included barium titanate,

82

calcium oxide,

83

calcium salts,

84

borates,

85

HTiNbO

5

,

86

and Eu

3+

dopants.

87

The sol-gel has a number of advantages over the conventional approach

in which separately prepared filler particles are blended into the un-cross-

linked elastomer before vulcanization.

88-90

The time-honored ex situ tech-

nique is difficult to control because the filler particles are generally

agglomerated

91

and the polymer is typically of high enough molecular

weight to make the viscosity of the mixture exceedingly high. Thus, the

blending technique is energy intensive and time consuming, and fre-

quently not entirely successful.

Because of the nature of the in situ precipitation, the particles are es-

sentially unagglomerated (as demonstrated by electron microscopy). The

mechanism for their growth seems to involve simple homogeneous nucle-

ation. Since the particles are separated by polymer, they do not have the

opportunity to coalesce. Figure 9.2 shows a typical transmission electron

micrograph of such a silica-filled material.

92

The particles are relatively

monodisperse, most having diameters in the range of 100-200 Å. Similar

results have been obtained with other particles formed by sol-gel