Environmental Engineering Reference

In-Depth Information

Riccardi et al., 1999; Mbumbia, et al., 2000; Montanaro et al., 2001; Cultrone,

et al., 2004; Lingling et al., 2005). Results from the present study revealed that

by sintering of jarosite-clay CCRs s/s products at 960º±2ºC, the mineralogical

phases of jarosite {KFe

3

(SO

4

)

2

(OH)

6}and

{2Fe

2

O

3

SO

3

.

5H

2

O} changed to

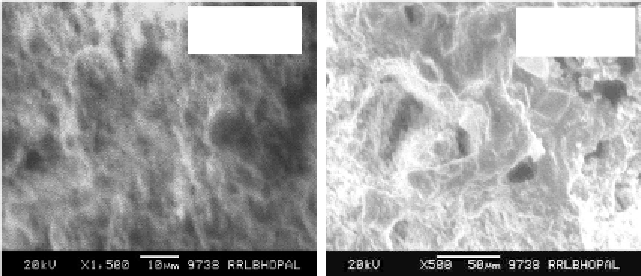

hematite and magnetite. Figure 10 shows SEM microstructure of fracture

surface of sintered jarosite waste composite brick made using jarosite waste to

clay ratio 1 with 15% PCCR.

15% PCCRs

30 % PCCRs

Figure 10. SEM microstructure of fracture surface of sintered jarosite waste composite

brick.

It appears that during firing of jarosite waste stabilized composites, a

considerable amount of liquid phase was formed, which might have reduced

the porosity and specific surface area under the capillary tension forces in the

fine pores resulting less water absorption and higher compressive strength.

This was further verified from the SEM microstructure of the fracture surface

of the jarosite composite bricks as shown in Figure 10 confirming the

densification of the composites which reduced the porosity, water absorption

and increased the density and compressive strength and thus could resist load

for engineering application. More details are reported elsewhere (Asokan,

2004).

3.2.4. Toxicity Leachate Characteristic Study

Earlier studies on s/s of toxic metal wastes using coke and coal

combustion by-products revealed that alkaline wastes can retain low

concentration of toxic metal ions and solidification and sorption of metals

were significant due to the presence of CaO and CaSO

4

in CCRs (Vempati et

Search WWH ::

Custom Search