Environmental Engineering Reference

In-Depth Information

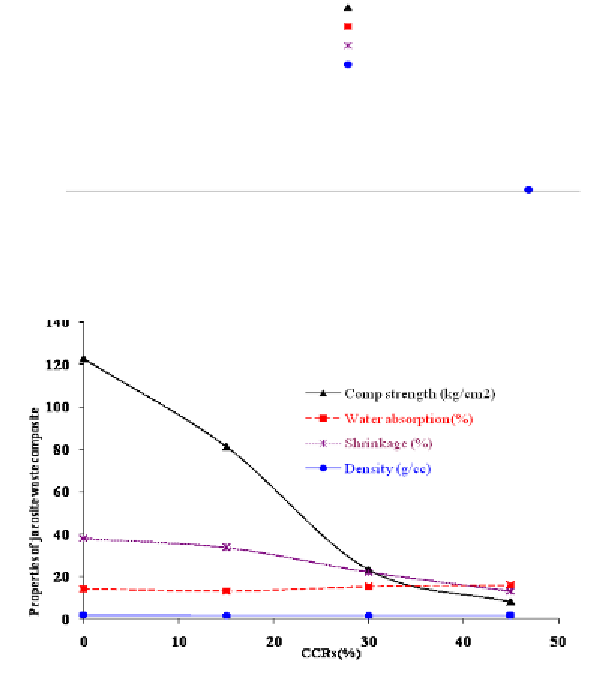

Comp strength (kg/cm2)

Water absorption(%)

Shrinkage (%)

Density (g/cc)

160

140

120

100

80

60

40

20

0

0

10

20

30

40

50

CCRs(%)

Figure 9 (c). Effect of CCRs on the mechanical properties of jarosite composites made

using jarosite waste to clay ratio 3 with CCRs.

Figure 9 (d). Effect of CCRs on the mechanical properties of jarosite composites made

using jarosite waste to clay ratio 4 with CCRs.

3.2.3. Effect of Sintering on Mineralogy and Microstructure of s/s

Jarosite Products

Firing of clay products leads to mineralogical, textural, and physical

changes that influence their quality. During high temperature firing, the

reaction behavior of temper grains (jarosite waste- clay matrix) is dominated

by dis-equilibrium conditions and characterized by the presence of different

reacting substances. When firing clay or compounds of silica and alumina

above 900 ºC, new crystallite phases are formed which are Al-Si spinel and

mullite (Peters and Iberg, 1978); Lingling et al., 2005). This is further

confirmed by earlier work on clay and pottery firing (Qrts, et al., 1993;

Search WWH ::

Custom Search