Environmental Engineering Reference

In-Depth Information

100

1.0

0.8

90

0.6

80

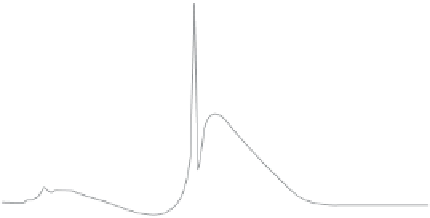

Ni% in Ni@C:45.6%

0.4

70

0.2

NiO residue: 57.9%

0.0

60

200

400

Temperature (°C)

600

800

figure 4.9

Thermogravimetric curves of the core@shell structured Ni@C NPs. Adapted with permission from Ref. [36]. © RSC.

where magnetic core@shell structured Ni@C NPs as well as liquid fuel products were generated. The former is an excellent

adsorbent that can be used for environmental remediation due to the high specific surface area of the carbon shell and the high

magnetization of the Ni core. liquid fuels produced from the PNCs contain more saturated components than those from PS,

which is attributed to catalytic hydrogenation by the Ni nanofiller during the pyrolysis process (Fig. 4.9).

4.4.2

Wastewater treatment—adsorption and/or redox remediation

A number of technologies for wastewater treatment and remediation, such as cyanide treatment [37], electrochemical precipi-

tation [38], reverse osmosis (RO) [39, 40], ion exchange (Ie) [41, 42], and adsorption [23, 43-49], have been developed. Among

these technologies, however, chlorination of cyanides can result in highly toxic intermediates and other toxic organochlorines.

These compounds together with residual chlorine create additional environmental problems. Precipitation is considered to be

the most applicable and economical approach, but this technique may generate a large amount of precipitate sludge that requires

additional processes for further treatment. Though RO can effectively reduce metal ions, its applications are limited due to high

costs and low pH value [50]. There are very limited studies on the removal of Cr(III) by Ie [41, 42, 51], and its operation cost

is also higher compared to other techniques [39]. In addition, Cr(vI) reduction by bulk zero-valence Fe [52, 53], Fe(II) [54, 55],

hydrogen [56, 57], dissolved organic compounds [58], and sulfur compounds [59] was also reported to have reached satisfac-

tory removal capacity over an extended treatment time.

More recently, nanostructured iron and iron oxides have proven highly efficient for heavy metal removal through either

reduction or adsorption [60-62]. However, using these nanomaterials still has two major challenges; one is easy oxidation/dis-

solution of pure Fe NPs especially in acidic solutions and the other is the recovery of minute NPs, especially in a continuous

flow system. To prevent oxidation/dissolution of NPs, a chemically inert shell structure is usually introduced around the NP

core. The shell material may include silica [63-66], polymer [67, 68], carbon [23], and noble metals [69-71]. Among these

alternatives, carbon shell has proven to be favorable due to its low cost and high specific surface area [72, 73]. Furthermore,

among the various carbon materials, graphene, an ultrathin and high surface area carbon structure, stands out as the best choice

as an adsorbent owing to its unique electronic and chemical structures. Magnetic graphene nanocomposites, with added

magnetic property as well as enhanced specific surface areas, have been prepared by our group, and have successfully been

applied as efficient and fast adsorbents in heavy metal remediation. Figure 4.10 demonstrates chromium removal efficiency by

pristine graphene and magnetic graphene nanocomposites; the latter demonstrated much higher efficiency than the former, and

within 5 min of treatment, Cr(vI) can be removed almost completely at an adsorbent loading level of 3.0 g/l.

4.4.3

Wastewater treatment—arsenic removal from Wastewater

Arsenic is another species that poses serious health and environmental concerns. In general, arsenic in inorganic form is more

toxic than in organic form, and arsenite [As(III)] is more mobile and toxic than arsenate [As(v)] [74]. There have been various

efforts on remediation of arsenic from the disposal scene, including ion exchange [75], RO [76], and adsorption. Compared to