Environmental Engineering Reference

In-Depth Information

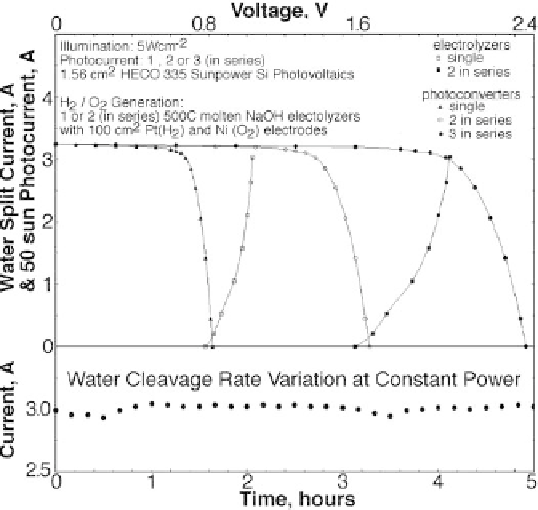

Figure 8.3.2

Photovoltaic and electrolysis charge transfer of STEP hydrogen using Si CPV's driving

molten NaOH water electrolysis. Photocurrent is shown for 1, 2 or 3 1.561 cm

2

HECO

335 Sunpower Si photovoltaics in series at 50 suns. The CPV's drive 500

◦

C molten

NaOH steam electrolysis using Pt gauze electrodes. Left inset: electrolysis current stability.

Modified with permission from Licht 2011.

Wang, 2006). Higher conductivity is desired as it leads to lower electrolysis ohmic

losses. Low carbonate melting points are achieved by a eutectic mix of alkali carbon-

ates (T

mp

Li

1

.

07

Na

0

.

93

CO

3

: 499

◦

C; Li

0

.

85

Na

0

.

61

K

0

.

54

CO

3

: 393

◦

C). Mass transport is

also improved at higher temperature; the conductivity increases from 0.9 to 2.1 S cm

−

1

with temperature increase from 650

◦

Cto875

◦

C for a 1:1:1 by mass mixture of the

three alkali carbonates (Kojima et al., 2008).

In 2009 we showed that molten carbonate electrolyzers can provide an effec-

tive media for solar splitting of CO

2

at high conversion efficiency. In 2010 Kaplan,

et al., and our group separately reported that molten lithiated carbonates provide a

particularly effective medium for the electrolytsis reduction of carbon dioxide (Licht

et al., 2010a; Kaplan et al., 2010). As we show in the photograph in Figure 8.3.3,

at 750

◦

C, carbon dioxide is captured in molten lithium carbonate electrolyte as solid

carbon by reduction at the cathode at low electrolysis potential. It is seen in the cyclic

voltammetry, CV, that a solid carbon peak that is observed at 750

◦

C is not evident

at 950

◦

C. At temperatures less than

900

◦

C in the molten electrolyte, solid carbon

is the preferred CO

2

splitting product, while carbon monoxide is the preferred prod-

uct at higher temperature. As seen in the main portion of the figure, the electrolysis

potential is

<

1.2 V at either 0.1 or 0.5 A/cm

2

, respectively at 750 or 850

◦

C. Hence,

∼

Search WWH ::

Custom Search