Environmental Engineering Reference

In-Depth Information

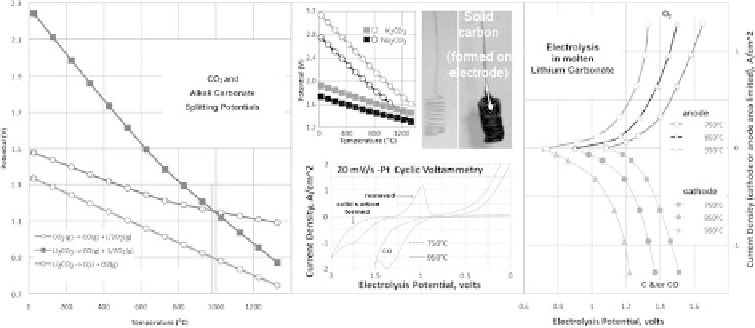

Figure 8.3.3

The calculated (left) and measured (right) electrolysis of CO

2

in molten carbonate. Left:

The calculated thermodynamic electrolysis potential for carbon capture and conversion

in Li

2

CO

3

(main figure), or Na

2

CO

3

or K

2

CO

3

(left middle); squares refer to M

2

CO

3

to

C

+

M

2

O

+

O

2

and circles to a M

2

CO

3

to CO

+

M

2

O

+

1/2O

2

. To the left of the vertical

brown line, solid carbon is the thermodynamically preferred (lower energy) product. To

the right of the vertical line, CO is preferred. Carbon dioxide fed into the electrolysis

chamber is converted to solid carbon in a single step. Photographs: coiled platinum cathode

before (left), and after (right), CO

2

splitting to solid carbon at 750

◦

C in molten carbonate

with a Ni anode. Right: The electrolysis full cell potential is measured, under anode or

cathode limiting conditions, at a platinum electrode for a range of stable anodic and

cathodic current densitites in molten Li

2

CO

3

. Lower midde: cathode size restricted full

cell cyclic voltammetry, CV, of Pt electrodes in molten Li

2

CO

3

. Modified with permission

from Licht et al. 2010a.

the electrolysis energy required at these elevated, molten temperatures is less than the

minimum energy required to split CO

2

to CO at 25

◦

C:

E

◦

(T

25

◦

C)

CO

2

→

CO

+

1

/

2O

2

=

=

1

.

33 V

(8.3.1)

The observed experimental carbon capture correlates with:

Li

2

CO

3

(molten)

→

C (solid)

+

Li

2

O (dissolved)

+

O

2

(gas)

(8.3.2A)

Li

2

CO

3

(molten)

→

CO (gas)

+

Li

2

O (dissolved)

+

1

/

2O

2

(gas)

(8.3.2B)

When CO

2

is bubbled in, a rapid reaction back to the original lithium carbonate is

strongly favored:

Li

2

O (dissolved)

+

CO

2

(gas)

→

Li

2

CO

3

(molten)

(8.3.3A)

Li

2

CO

3

→

Li

2

O

+

CO

2

(8.3.3B)

In the presence of carbon dioxide, reaction (8.3.3A) is strongly favored (exothermic),

and the rapid reaction back to the original lithium carbonate occurs while CO

2

is

bubbled into molten lithium carbonate containing the lithium oxide.

Search WWH ::

Custom Search