Environmental Engineering Reference

In-Depth Information

Triaxial Shear Strength

Apparatus and Procedures

General description is given in

Section 3.4.4

and, as applicable to rock testing, in

Section

3.5.3

and in

Table 3.28.

Strength Values

Studies have been made relating analysis of petrographic thin sections of sandstone to esti-

mates of the triaxial compressive strength (Fahy and Guccione, 1979). Relationships have

been developed for approximating peak strengths for rock masses (Hoek and Brown, 1980).

Direct Shear Strength

Purpose

The purpose is to obtain measurements of the parameters

and

c in situ

. It is particularly

useful to measure strength along joints or other weakness planes in rock masses.

φ

In Situ Test Procedure

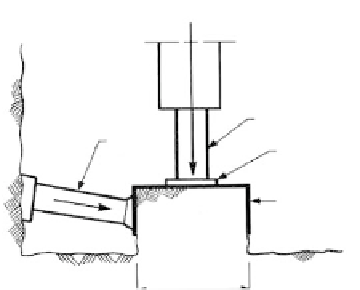

A diamond saw is used to trim a rock block from the mass with dimensions 0.7 to 1.0 m

2

and 0.3 m in height, and a steel box is placed over the block and filled with grout

(Haverland and Slebir, 1972). Vertical load is imposed by a hydraulic jack, while a shear

force is imposed by another jack (Figure 3.43) until failure. All jack forces and block move-

ments are measured and recorded. Deere (1976) suggests at least five tests for each geo-

logic feature to be tested, each test being run at a different level of normal stress to allow

the construction of Mohr's envelope.

Laboratory Direct Shear Tests (See

Section 3.4.4)

If the specimen is decomposed to the extent that it may be trimmed into the direct shear

ring (

Figures 3.37c

and

3.51)

the test is performed similar to a soil test (Section 3.4.4). If pos-

sible, the shearing plane should coincide with the weakness planes of the specimen. Tests

to measure the characteristics of joints in fresh to moderately weathered rock are performed

by encapsulating the specimen in some strong material within the shear box as shown in

Figure 3.37d (ISRM, 1981). The specimen is permitted to consolidate under a normal force

and then sheared to obtain measures of peak and residual strength as described in Section

3.4.4. The normal stress is increased, consolidation permitted, and the specimen sheared

again. The process is repeated until five values of shear stress vs. normal stress is obtained,

from which a graph for peak and residual strength is constructed as shown in

Figure 3.44.

Reaction

Load jack

Steel pad

Thrust

jack

Steel frame

Rock

block

FIGURE 3.43

In situ

direct shear test.

1

−

0.7 m