Environmental Engineering Reference

In-Depth Information

Figure 2-7 shows a schematic diagram of the internal structure of a typical composite

wind turbine blade. The standard

x-y coordinate system

for describing the complex curved

surfaces of an airfoil has its origin at the leading edge, with the positive

x

or

chordwise

di-

mension extending aft to the trailing edge, and the positive

y

or

thickness

dimension extend-

ing toward the

low-pressure

or

upper surface

of the airfoil. Negative

y

dimensions then point

to the

high-pressure

or

lower surface

. The upper- and lower-surface designations have their

basis in airplane wing descriptions. Both the

x

and

y

dimensions are typically normalized by

the chord width

c

.

The structural arrangement in Figure 2-7 is representative of current commercial blade

designs [Grifin 2001]. The primary structural member is a

box-spar

, with

shear webs

lo-

cated approximately 15 percent and 50 percent of the chord width measured from the leading

edge, with a substantial build-up of

spar cap

material between these two webs. Exterior skins

and internal shear webs are both of sandwich construction, in which iberglass laminate skins

are separated by balsa cores.

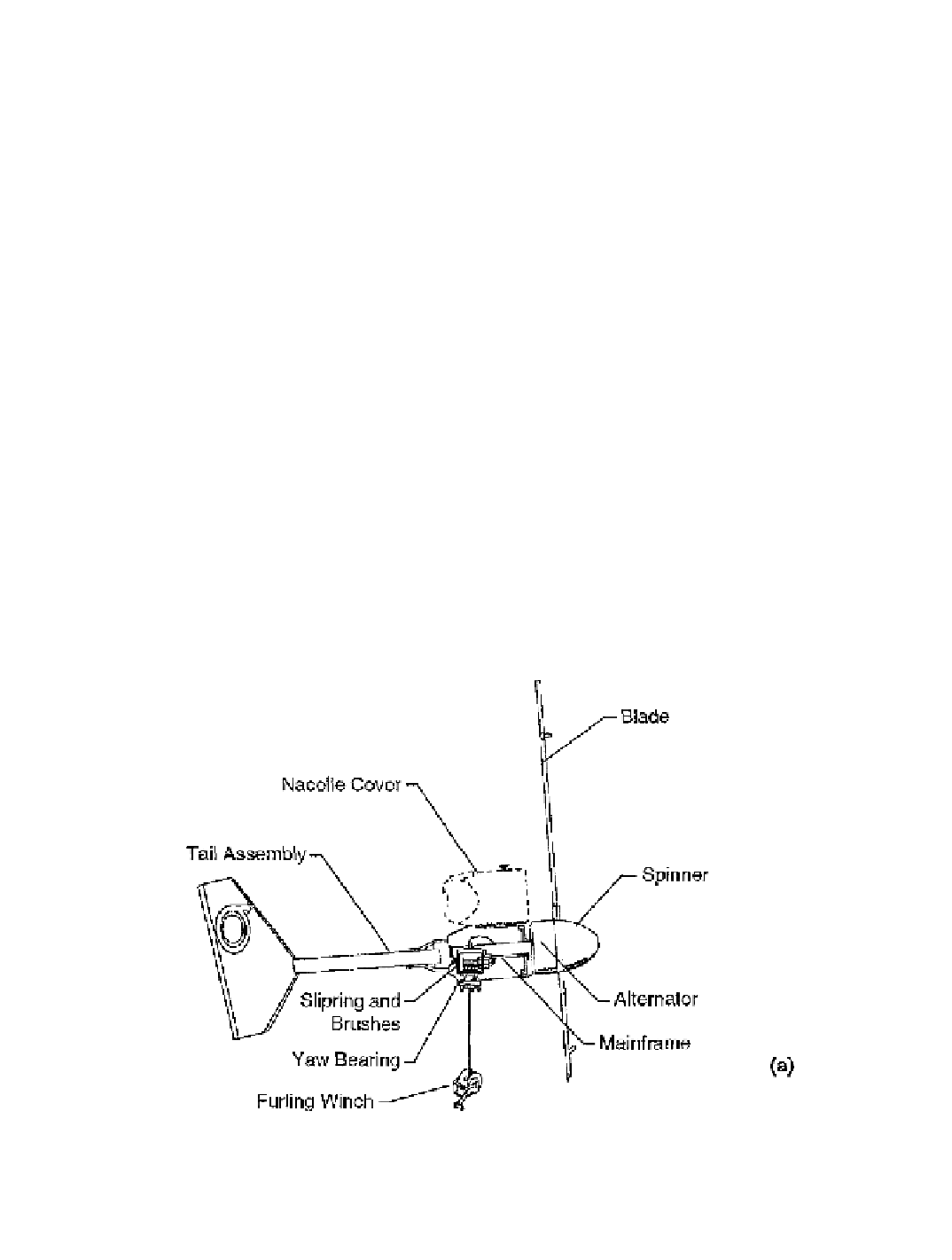

The Power-Train Subsystem

The

power train

of a wind turbine consists of the series of mechanical and electrical

components required to convert the mechanical power received from the rotor hub to elec-

trical power. In a HAWT, this equipment is atop the tower, so low maintenance is an im-

portant design requirement. Examples of small-, medium-, and large-scale power trains are

illustrated in Figure 2-8. A typical HAWT power train consists of a

turbine shaft assembly

(also called a low-speed or primary shaft), a

speed-increasing gearbox

, a

generator drive

shaft

(also called a high-speed or secondary shaft), a

rotor brake

, and an

electrical genera-

tor

, plus auxiliary equipment for control, lubrication, and cooling functions. As illustrated in

Figure 2-8(a), some small-scale HAWTs and a few medium- and large-scale HAWTs have

a

direct-drive

from the turbine to the generator, with no gearbox.

Figures 2-8. Typical HAWT power trains.

(a) Small-scale: Bergey BWC-1500/1.5 kW

(

Courtesy of Bergey Windpower Company, Inc

.)

Search WWH ::

Custom Search