Environmental Engineering Reference

In-Depth Information

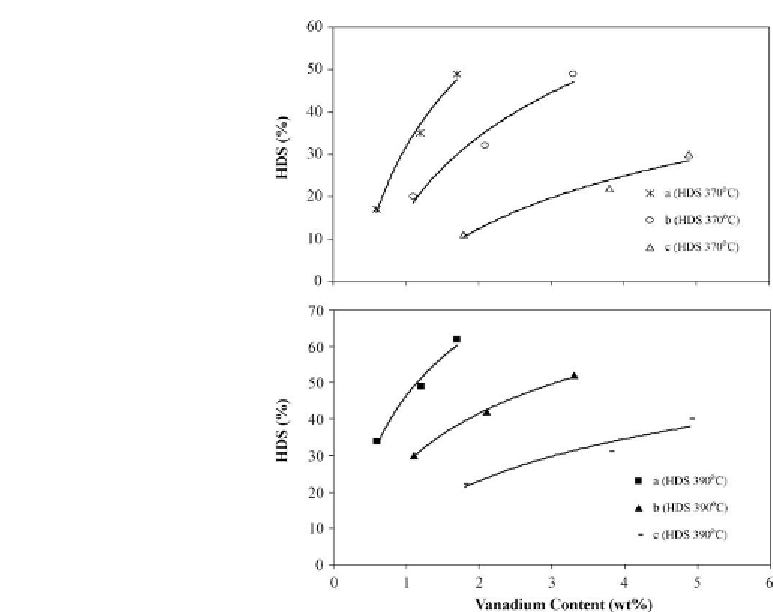

Figure 9.7: Effect of V content of catalysts reprocessed from coked spent catalysts (a: catalyst A;

b: catalyst B; c: catalyst C) on hydrodesulfurization (HDS) activity at 370 and 390

C [From

ref.

522

. Reprinted with permission].

120 A. The performance of the catalyst for residual oil hydroprocessing was found to be

roughly equal to that of a commercial catalyst.

9.1.1.3 Effect of Hydrothermal Treatment on Reprocessed Catalysts

The activity of the reprocessed catalysts can be significantly enhanced by subjecting spent

hydroprocessing catalysts to hydrothermal treatment at 300

◦

C for 2 h

[524]

. The pore volume

and pore size distribution of the spent catalysts before and after hydrothermal treatment are

compared in

Fig. 9.9

. It is seen that the pore volume after hydrothermal treatment increased

from 0.24 to 0.48 mL/g, whereas surface area increased from 37 to 70 m

2

/g. The volume of

pores in the 100-2000 A diameter range increased from 0.16 to 0.38 mL/g, while the mesopore

volume in the 100-500 A increased from 0.12 to 0.24 mL/g.

A hydrothermally treated spent catalyst was used to prepare reprocessed catalysts using

boehmite in similar manner as described above (

Fig. 9.1

), i.e., 20, 40, and 60 wt.% of the