Environmental Engineering Reference

In-Depth Information

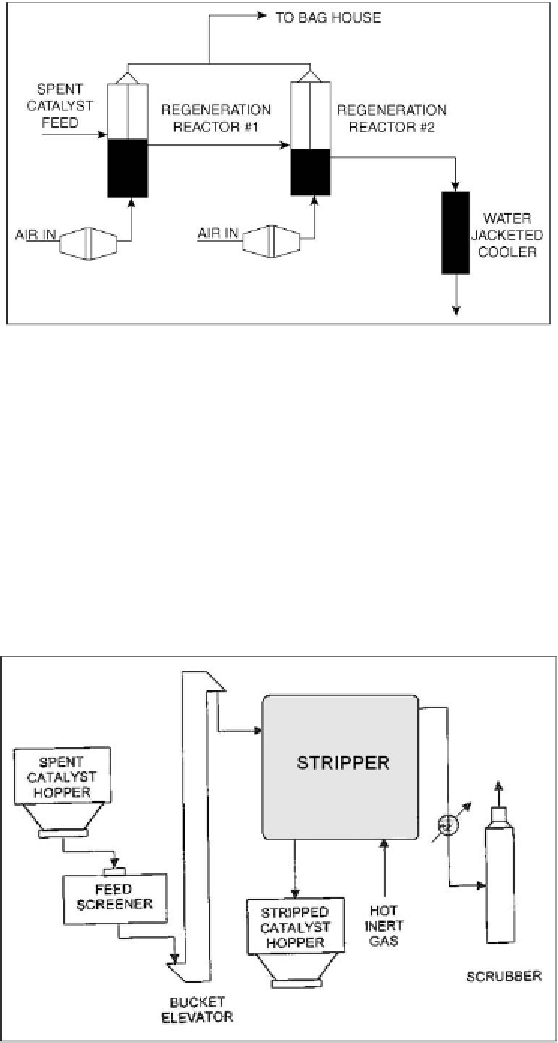

Figure 6.42: Ebullated bed reactors of TRICAT regeneration process [From refs

471

and

472

.

Reprinted with permission].

reactor. The regeneration temperature is maintained in the range of 450-510

◦

C. Regenerated

catalyst passes through the water-jacketed cooler before screening and packaging.

The stripper (

Fig. 6.43

)

[471]

, which is part of the TRP process, is usually engaged to achieve

a uniformity of regeneration. Without stripping, an erratic performance and poor temperature

control could be encountered. The aim is to remove the excess water and hydrocarbons. This is

Figure 6.43: Catalyst stripping system of TRICAT regeneration process [From ref.

471

. Reprinted

with permission].