Environmental Engineering Reference

In-Depth Information

reused or discarded, or alternatively, the slag is transported in a liquid state to a cleaning

operation or slag dump (

Case 6.6

).

Drosses and skimmings

result from the oxidation of metals at the bath surface or by

reactions with fireproof material used as furnace linings.

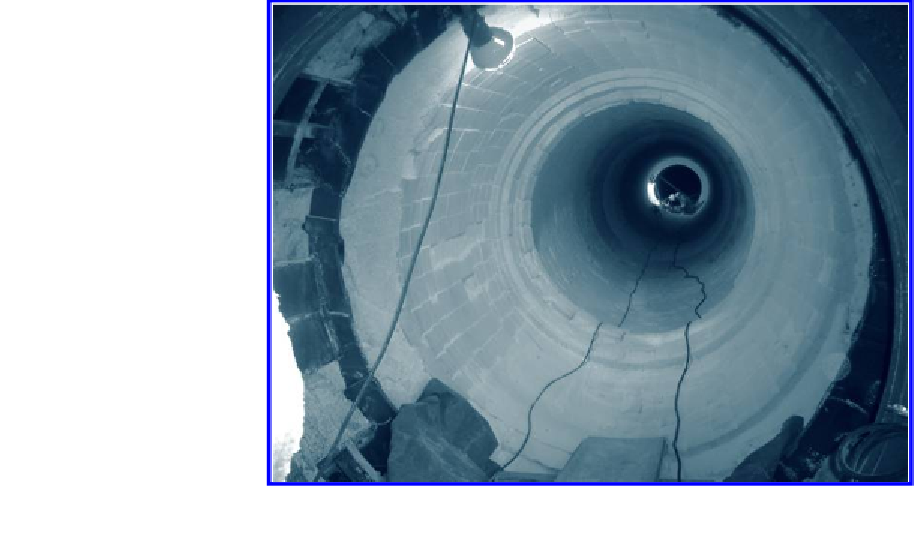

Spent linings and refractories

result when refractory material falls out of the furnace

linings or when the furnace lining has to be replaced completely (

Figure 6.14

).

Pollution abatement systems wastes and residues

include flue gas dust and sludge recov-

ered from the air pollution control equipment as well as other solids such as spent filter

materials. Sulphuric acid and liquid sulphur dioxide are also wastes/residues from pollu-

tion abatement systems as discussed above. In addition, wastewater treatment plants gen-

erate metal-containing sludge.

Hydrometallurgical wastes and residues

include sludge generated in the leaching proc-

ess. Purification and electrolysis processes can generate metal rich solids such as anode

slime. Other wastes and residues typically produced are oils and greases and industrial

scrap such as steel and wood wastes.

In terms of quantity, slag as the final product of unwanted materials, contributes to most

of the solid waste outputs of a smelter. Not all slag is waste. Depending on the smelter type

and mineral process, slag can be a valuable by-product to be used as construction material

or for sand blasting (Borell 2005) (

Case 6.7

). When slag is rapidly cooled by instant granu-

lation in water, a stable granular product is formed. The granulated slag is often virtually

completely amorphous (glassy). Remaining trace metals incorporated in glass phases show

a low solubility in comparison with those existing mainly in crystalline phases (Konradsson

2003), a characteristic that holds metals immobile in granulated copper slag and in most

other slag.

Alternative materials are often labelled as waste which puts focus on their assumed envi-

ronmental properties. Concerns about assumed environmental risks are sometimes a barrier

to a wider use of alternative materials. A far too common approach is to classify a mate-

rial based only on its total chemical analysis (say metal content) without further analysis of

In terms of quantity, slag as

the fi nal product of unwanted

materials, contributes to most

of the solid waste outputs of a

smelter.

FIGURE 6.14

Renewing the Furnace Linings of a

Rotary Furnace

Search WWH ::

Custom Search