Environmental Engineering Reference

In-Depth Information

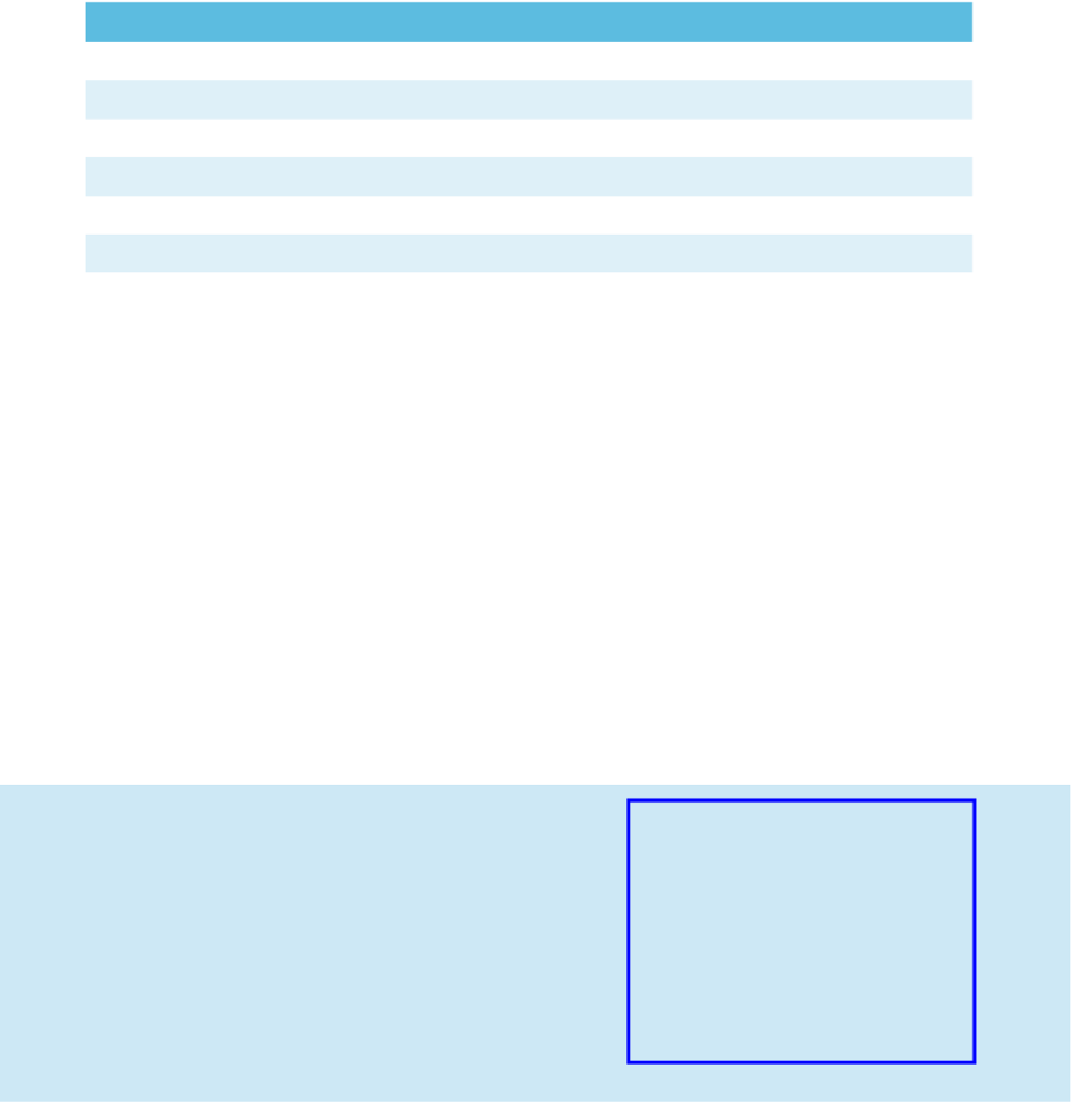

TABLE 6.6

Laboratory Leaching Test Methods -

A far too common approach is to classify a material based only on the chemical assays. The appropriate approach for

assessing environmental characteristics of solid materials is by laboratory leaching testing

Type of Leaching Test

Test Standard

Column-leaching test

(EN 14405)

Two-stage agitated leaching test

(EN 12457-3)

Availability-leaching test

(NT Envir 003)

Oxidized availability leaching test

(NT Envir 006)

pH-static leaching test

(CEN/TC 292/WG6)

The US EPA Toxicity Characteristic Leaching Procedure (TCLP)

Test method 1311

how metals are bound in the matrix. The appropriate approach for assessing environmental

characteristics of slag is in form of laboratory leach testing. A variety of factors influence the

leaching characteristics of different elements. A variety of different standard tests are used

to characterize the leaching properties of a material (

Table 6.6

).

Column tests and two-stage serial batch tests are frequently used for the characteriza-

tion of by-products, including materials to be characterized before land filling. A leachate

test predicts whether a material is likely to leach contaminants, specifically metals, at levels

of concern. The material is subjected to an extraction fluid (e.g. a basic or buffered solu-

tion) and then the resulting extract is analyzed and compared to a leachate criteria list. If the

resulting concentration is equal to or in excess of the concentration specified for that con-

taminant in the applicable schedules, the material is considered leachate toxic and may be

considered potentially toxic or hazardous. In addition, the material may require treatment

to eliminate or reduce the leaching potential prior to disposal or may require disposal in a

secure, hazardous waste landfill.

The second main category of solid waste streams originates from air pollution controls

(e.g. gypsum from scrubbers) and water treatment facilities. These wastes are usually haz-

ardous and in the form of sludge. Final disposal is difficult and generally costly. Modern

smelting technologies aim to reduce gaseous and solid waste emissions. Wastes destined for

disposal from metal production are kept to a minimum. Flue dusts are typically recycled to

A leachate test predicts whether

a material is likely to leach

contaminants, specifi cally metals,

at levels of concern.

CASE 6.6

Slag Disposal into the Environment - An Environmental

Eyesore or Reason for Concern?

The nickel mining and smelting operation of INCO in

Sulawesi, Indonesia commenced about four decades ago and

has been in operation since then. The ferro-nickel smelter

produces slag at a rate of several tons per hour, which is

dumped at valleys nearby the smelter. While leachate test-

ing indicates that the slag is inert, the practice continually

invites mine opponents to criticize the mining

operation in general and the slag disposal

practice in particular. Claims continue to

be made that leachate from slag disposal

sites cause environmental damage to

groundwater and surface water runoff.

Search WWH ::

Custom Search