Environmental Engineering Reference

In-Depth Information

Products

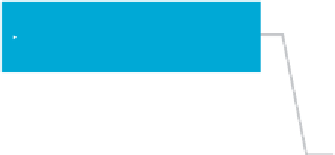

Commodity Hydrate 141,000 t/yr

47,000 t/yr

180,000 t/yr

25,000 t/yr

Bauxite Ore from Mine

Speciality Hydrate

Ore from Mine

1,852,595 t/yr

850,000 t/yr

Commodity Alumina

Washed Ore

Speciality Alumina

BAUXITE PREPARATION

AND ALUMINA PRODUCTION

Water

Mine Wastes

Mining

Fresh Water from

River

Tailings

Bauxite Residue

1,002,595 t/yr

235,200 t/yr

Washing

Comminution

Digestion

Separation

Precipitation

Calcination

Power Plant

Other Supporting Activites

937 m

3

/hr

Energy

Coal

Gaseous Emissions

Power Plant

Alumina Plant

155,000 t/yr

11,040 m

3

/yr

110,000 dry Nm

3

/h

100,000 dry Nm

3

/h

Fuel (IDO)

Auxiliary Materials

Caustic Soda

Hydrate Lime

Sulphuric Acid

Flocculant

58,000 t/yr

9,000 t/yr

1,500 t/yr

120 t/yr

Aqueous Emissions

Waste Water Treatment Plant

Water Pool

Tailings Pond

28 m

3

/hr

664 m

3

/hr

200 m

3

/hr

FIGURE 2.6

Indicative Mine Inputs and Outputs

for a Hypothetical Maximum Mine

Operation Illustrated

a biologist, an environmental engineer, or a physicist reviews the mining project (a trend

often repeated by the approval authorities).

The review of the project design is critical. Is acid generation likely, and if so when and

where? Which metals are likely to remain in the mine waste, and at what concentrations?

Does the process produce acidic or caustic efl uents? Does an alternate tailings detoxii cation

scheme exist? What are the technical implications of relocating the mill site? Is backi lling

of tailings a realistic option? Admittedly the answer to most technical questions is best left to

the project proponent. After all, the mining company owns the EIA, and the preparation of

the EIA is a team effort: the mining company is providing technical expertise; environmen-

tal input is outsourced to environmental specialists. However, for the biologist, the environ-

mental engineer, or the physicist to meaningfully participate in the impact assessment, and

to ask the right questions, experience with and knowledge of the mining sector is essential.

A methodological approach to the project review will help. Firstly, what are the main

mine inputs and outputs (see

Figure 2.6

as an example)?

The next question is: What characterizes emissions? For each emission stream (that is,

emissions to air, emissions to water and waste emissions), list source, quantity, quality or

characteristic, and discharge point and/or management option as illustrated in

Figure 2.7

.

Once this exercise is completed, there is a good understanding of the various waste streams

and emissions associated with the mine development.

For the biologist, the

environmental engineer, or

the physicist to meaningfully

participate in the impact

assessment, and to ask the right

questions, experience with and

knowledge of the mining sector

is essential.

Assess Project Alternatives

The section in which project alternatives are addressed is often called the heart of an envir-

onmental impact assessment because it organizes and clarii es the choices available to the

decision makers. The project proponent, the approval authority, or the public can generate

alternatives, including the 'no action' alternative (see the section below on establishing the

environmental baseline). While generally the assessment of alternatives can relate to both

the design and the location of a project, alternative siting of a mine is understandably not an

option. However, alternative methods exist to accomplish the proposed action, such as differ-

ent mining and mineral processing methods, alternative size or production rate, different tim-

ing in mine development, different layouts of supporting mine infrastructure, and different

The credibility of the

environmental impact assessment

is at risk if the mine proposal

is identifi ed as the preferred

solution and is put into a

favourable light by comparing it

to poor or 'straw man' alternative

solutions.

Search WWH ::

Custom Search