Environmental Engineering Reference

In-Depth Information

OH

OH

O

O

HO

O

O

HO

O

OH

n

Hydrogen

Cellulose

OH

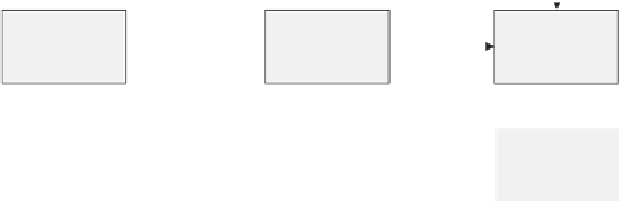

Aqueous mixture:

levulinic acid +

formic acid + H

2

SO

4

Levulinic acid

+ solvent

Cellulose

hydrolysis

Hydrogenation

unit

Extraction

H

2

SO

4

/H

2

O

γ

-Valerolactone

+ solvent

Solvent recycling

Distillation

-Valerolactone

γ

FIGURE 18.12

Process integration concept for gVL production.

Disadvantages of this process are the need for a solvent; solvent recycling

always leads to solvent losses, which are generally in the range of 20%. The hand-

ling of sulfuric acid streams is accompanied by environmental, corrosion, and

safety issues.

18.5 DIRECT AQUEOUS REFORMING OF SUGARS

LEADING TO A RANGE OF ALKANES

Aqueous-phase reforming (APR) of sugars and polyols was initially developed as a

technology to produce renewable hydrogen (+CO

x

). However, nowadays, by an

appropriate choice of catalyst, substantial amounts of light alkanes and monofunc-

tional compounds can be produced as well (Alonso et al., 2010).

To illustrate the principle of this technology, which is promoted by the company

Virent (tinyurl.com/q89rwxe), the equation is given for the conversion of glucose into

its fully saturated analogue hexane:

19C

6

H

14

O

6

!

13C

6

H

14

+36CO

2

+42H

2

O

ð

RX

:

18

:

1

Þ

The fact that no external hydrogen is needed makes this a relatively cheap technology.

However, from this equation, it follows that carbon atom efficiency can never exceed

the value of 68%. Another disadvantage is that selectivities for saturated C4

-

C6

alkanes are low, because generally lower alkanes (<C4) are formed.

Typically, supported Pt catalysts are used. The nature of both the metal and the

support significantly influences the APR reactions of aqueous solutions of sugars with

C/O ratios of 1. As the acidity of the catalytic system increases, e.g., with a solid acid

catalyst support such as SiO

2

and Al

2

O

3

, the selectivity to alkanes increases due to the

Search WWH ::

Custom Search