Graphics Reference

In-Depth Information

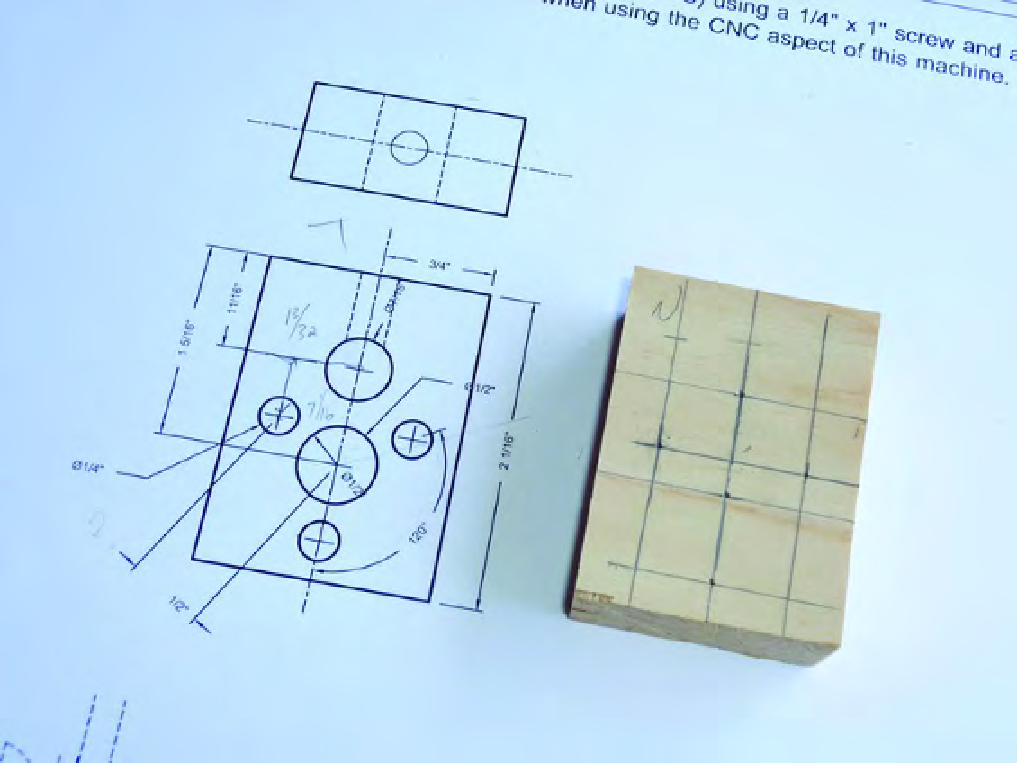

Figure 6-2. Part N marked with penciled lines to indicate drill points

Notice in Figure 6-2 how the actual Part N is identical in size to the drawing. This is a benefit to

printing out the building plans at actual size.

The three small holes you'll drill on the face of Part N have a diameter of 1/4” to match the flange

holes of the three nuts to be inserted. The hole centered between the three small holes has a diameter of

1/2” that serves as the pass-through hole for the lead screw. Finally, the mid-size hole drilled above the

1/2” hole has a diameter of 7/16” and is the hole that will intersect the 1/4” hole drilled into the edge of

Part N. This hole will carry the cross dowel (barrel nut) and the edge hole will receive the 1/4" screw to

screw into the cross dowel for mounting to the ZY Plate.

Don't forget this edge hole! In Figure 6-2 you can see that the 1/4” edge hole is drilled in such a way

that it intersects the 7/16” hole on the face of Part N. The dashed lines in the drawing represent the

depth of the 1/4” hole drilled on the edge.

After you've drilled the face holes, your piece should look like the one in Figure 6-3.

Search WWH ::

Custom Search