Civil Engineering Reference

In-Depth Information

b

o

d

p

d

p

b

o

h

sc

h

sc

h

p

h

p

Ce

ntroidal axis of sheet

e

Ce

ntroidal axis of sheet

e

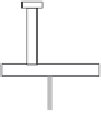

Figure 2.15 Composite beam with profiled steel decking spanning the same direction.

market that eliminated the use of traditional timber temporary forms. Ini-

tially, the new decking system served only as a replacement for the timber

formwork due to its advantages of serving as a working platform to support

the construction loads, as well as a permanent formwork for the concrete.

Once the sheets had their surfaces suitably embossed with small indentations

to ensure reliable bond with the concrete, it became an integral structural

element of the slab by providing all or a part of the main tension reinforce-

ment, and it was eventually incorporated into the overall composite floor

and framing system. Since the decking created a barrier between the con-

crete slab and the steel beam, holes were initially cut or punched into the

deck for the welding of the stud shear connectors, but it soon became pos-

sible to weld these connectors through the decking. The disadvantages of

this form of construction were the operation and cost of welding the con-

nectors through the decking on site, the limitations to maximum spans to

about 3.5 m without propping, and the addition of framing, and a “wet

trade” is involved in pouring the concrete floor that prevents a dry construc-

tion environment.

The use of composite construction can be seen now between steel beams

and different concrete slabs. As an example, the use of prestressed hollow

core concrete slabs in conjunction with steel beams to provide composite

action is a new form of construction. In this construction, the prestressed

hollow core concrete units are placed on the top of the steel beam as shown

in

Figure 2.16

. Tie steel is placed on site into the slots made at the top of the

hollow cores, which are filled with grade C25 (minimum)

in situ

concrete.

The slab rests directly on the top of the flange of the steel beam as shown in

Figure 2.16

, and shear connectors are used to ensure the composite action

between the prestressed hollow core concrete floor and the steel beam.

with hollow core concrete units. The longitudinal and transverse joints

between the hollow core concrete units are filled with

in situ

concrete so

that horizontal compressive membrane forces can be transferred through

Search WWH ::

Custom Search