Civil Engineering Reference

In-Depth Information

load-slip behavior of the connector was also of equal importance. The slip

at the steel-concrete interface depends on many factors such as type of con-

nector, size of shear connector, spacing between connectors, type of floor

slab, and concrete strength of slab. To evaluate the load-slip behavior of

the connector taking into account all parameters that affect the shear con-

nection, an unlimited number of expensive push-off tests would need to

be carried out. Numerical modeling of push-off tests can be used in carrying

out extensive parametric studies to evaluate the load-slip behavior of the

shear connector.

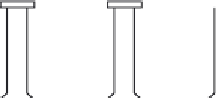

The development of the electric drawn arc stud welding apparatus in

1954 allowed a type of shear connector known as the headed stud connector

(see

Figure 2.14

)

to be rapidly fastened to the top flange of the steel beams

in situ

. Due to its advantages over other forms of shear connection, such as

rapid installation and the fact that they were equally strong and stiff in shear

in all directions normal to the axis of the stud, the stud connector became

one of the most popular types of connector used in composite construction.

Studies of stud connectors did not begin until 1956. Push-off tests on stud

studs with an upset head of diameter ranging from 0.5 (13 mm) to

1.25 in. (32 mm). Fatigue and static tests were also performed by Thurli-

studs and, to a lesser extent, 0.75 in. (19 mm) diameter straight studs with

an upset head. All the push-off tests showed that steel studs are suitable

for use as shear connectors and that the behavior of a stud connector is similar

to that of a flexible channel connector. The shear capacity was found to be a

function of the diameter and height of the stud and of the strength of the

concrete.

During the latter half of the 1950s, profiled steel sheeting (decking) (see

Figure 2.15

)

was introduced in the North American steel construction

Not less than 1.5 d

Auto

matic stu

d weld

d

20 mm min.

Figure 2.14 Headed stud shear connector.

Search WWH ::

Custom Search