Civil Engineering Reference

In-Depth Information

the prestressing tendons shall have adequate ductility, as specified in EN

stressing tendons obtain the specified value of the elongation at maximum

load given in EN 10138. Adequate ductility in tension may be assumed

for the prestressing tendons if

f

pk

/

f

p0.lk

k

. The value of

k

specified in

EC2 is 1.1. EC2 also specifies that prestressing tendons shall have adequate

fatigue strength. The fatigue stress range for prestressing tendons shall be in

basis of the nominal cross-sectional area of the prestressing steel and the char-

acteristic values

f

p0.lk

,

f

pk

, and

e

uk

. The design value for the modulus of elas-

ticity,

E

P

, may be assumed equal to 205 GPa for wires and bars. The actual

value can range from 195 to 210 GPa, depending on the manufacturing pro-

cess. The design value for the modulus of elasticity,

E

P

, may be assumed

equal to 195 GPa for a strand. The actual value can range from 185 to

205 GPa, depending on the manufacturing process. The mean density of

prestressing tendons for the purposes of design may normally be taken as

7850 kg/m

3

. The values given earlier may be assumed to be valid within

a temperature range between

40 and +100

C for the prestressing steel

in the finished structure. The design value for the steel stress,

f

pd

, is taken

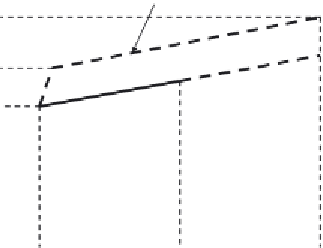

branch with a strain limit

e

ud

or a horizontal top branch without strain limit

can be utilized. The design may also be based on the actual stress-strain rela-

tionship, if this is known, with stress above the elastic limit reduced analo-

gously (see

Figure 2.11

)

. It should be noted that, according to EC2, the

recommended value for

e

ud

is 0.9

e

uk

. If more accurate values are not known,

s

Idealized

f

pk

f

pk

/

g

s

f

0.1pk

f

pd

=

f

p0.1k

/

g

s

Design

e

e

ud

f

pd

/

E

p

e

uk

Figure 2.13 Idealized and design stress-strain diagrams for prestressing steel specified

Search WWH ::

Custom Search