Civil Engineering Reference

In-Depth Information

wires or strands for ordinary prestressing and low-relaxation tendons, respec-

tively, whereas Expression

(2.35)

applies to hot-rolled and processed bars:

0

:

75 1

m

Class1

D

s

pr

t

1000

ð

Þ

10

5

39

r

1000

e

6

:

7

m

s

pi

¼

5

:

ð

2

:

33

Þ

1000

0

:

75 1

m

Class2

D

s

pr

t

ð

Þ

10

5

66

r

1000

e

9

:

1

m

s

pi

¼

0

:

ð

2

:

34

Þ

0

:

75 1

m

Class3

D

s

pr

t

1000

ð

Þ

98

r

1000

e

8

m

10

5

s

pi

¼

1

:

ð

2

:

35

Þ

where

D

s

pr

is the absolute value of the relaxation losses of the prestress,

s

pi

;

for posttensioning,

s

pi

is the absolute value of the initial prestress

s

pi

¼s

pm0

and, for pretensioning, is the maximum tensile stress applied to the tendon

minus the immediate losses occurred during the stressing process;

t

is the

time after tensioning (in hours);

m¼s

pi

/

f

pk

where

f

pk

is the characteristic

value of the tensile strength of the prestressing steel; and

r

1000

is the value

of relaxation loss (in %), at 1000 h after tensioning and at a mean temperature

of 20

C. The long-term (final) values of the relaxation losses may be esti-

mated for a time

t

equal to 500,000 h (i.e., around 57 years).

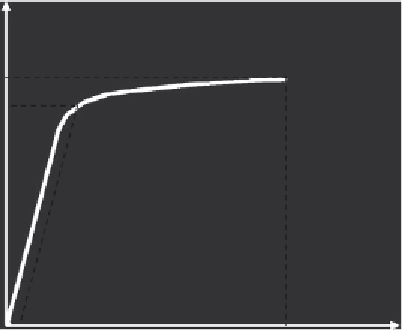

The 0.1% proof stress (

f

p0.lk

) and the specified value of the tensile strength

(

f

pk

) are defined as the characteristic value of the 0.1% proof load and the

characteristic maximum load in axial tension, respectively, divided by the

nominal cross-sectional area as shown in

Figure 2.12

.

According to EC2,

s

f

pk

f

p0.1k

e

e

uk

Search WWH ::

Custom Search