Civil Engineering Reference

In-Depth Information

656 MPa, respectively. The web of the steel plate girders was strengthened

by stiffeners as shown in

Figure 7.8

to prevent shear failure. The concrete

slab had a width of 2184 mm and a depth of 181 mm. The composite plate

girder had an overall height of 980 mm. The measured concrete cylinder

strength of G2 was 52.5 MPa. The concrete slab had reinforcement steel

bars, as shown in

Figure 7.8

,

of Grade 60 having a yield stress of

413 MPa (60 ksi). The reinforcement bars were spaced at 209 mm longitu-

dinally and 356 mm transversely. The top and bottom reinforcement bars

had a cover of 44 mm. The shear connectors were headed studs having a

diameter of 19 mm and a height of 114 mm. Sixty pairs of headed studs were

used in the composite plate girder G2 as shown in

Figure 7.8

.

The composite

plate girders were subjected to a single concentrated load applied at midspan

via a spreader beam. The loading was applied in increments using displace-

ment control.

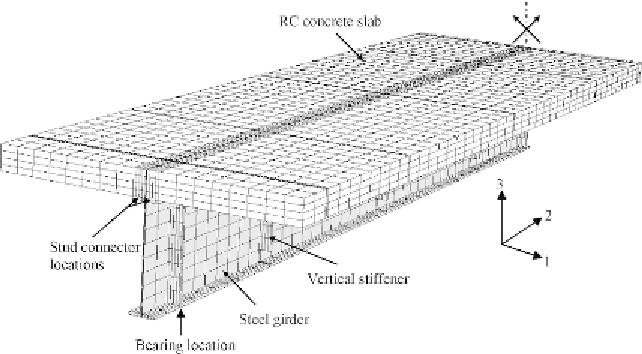

The composite plate girder G2 tested by Mans [

7.29

] was modeled in this

book using ABAQUS [1.29]. The finite element analysis has accounted for

the nonlinear material properties and geometry of the components as well as

the interfaces between the components. The steel-concrete composite plate

girder components were modeled using 3-D solid elements (C3D8) avail-

able in the ABAQUS [1.29] element library. Only half of the composite

plate girder was modeled due to symmetry as shown in

Figure 7.9

. The total

number of elements used in the model shown in

Figure 7.9

was 7266. Dif-

ferent mesh sizes were tried to choose the reasonable mesh that provides

Figure 7.9 Finite element mesh of composite girder G2.

Search WWH ::

Custom Search