Civil Engineering Reference

In-Depth Information

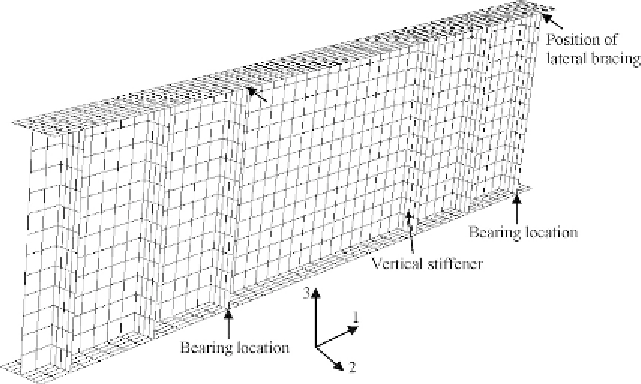

Figure 6.10 Finite element mesh of the small-scale built-up I-section plate girder T2.

The hinged support of T2, shown in

Figure 6.9

,

was prevented from dis-

placement in the horizontal direction (direction 1-1 in

Figure 6.10

)

and the

vertical direction (direction 3-3 in

Figure 6.10

). On the other hand, the

roller support of T2, shown in

Figure 6.9

,

was prevented from displacement

in the vertical direction only (direction 3-3 in

Figure 6.10

)

. To account for

the lateral restraints of the compression flange, the top compression flange

was prevented from lateral displacements, in direction 2-2 of

Figure 6.10

,

at the end supports, which is identical to the test T2. The load was applied

in increments as concentrated static load, which is also identical to the exper-

imental investigation. The nonlinear geometry was included to deal with the

large displacement analysis.

The stress-strain curve for the structural steel given in the EC3 [2.11] was

adopted in this study with measured values of the yield stress (

f

ys

) and ulti-

ABAQUS [1.29] (using the PLASTIC option) allows a nonlinear stress-

strain curve to be used (see Section 5.4.2 of

Chapter 5

). The first part of

the nonlinear curve represents the elastic part up to the proportional limit

stress with Young's modulus of (

E

) 200 GPa and Poisson's ratio of 0.3 used

in the finite element model. Since the buckling analysis involves large inelas-

tic strains, the nominal (engineering) static stress-strain curves were con-

verted to true stress and logarithmic plastic true strain curves as detailed

in Section 5.4.2.

Search WWH ::

Custom Search