Civil Engineering Reference

In-Depth Information

part concerned. The center-to-center spacing of fillet welds all round should

not exceed the value necessary to prevent local buckling.

Also, according to EC3 (BS EN 1993-1-8) [2.13], a full penetration butt

weld is defined as a weld that has complete penetration and fusion of weld

and parent metal throughout the thickness of the joint. A partial penetration

butt weld is defined as a weld that has joint penetration that is less than the

full thickness of the parent material. Intermittent butt welds should not be

used. Plug welds may be used to transmit shear, to prevent the buckling or

separation of lapped parts, and to interconnect the components of built-up

members but should not be used to resist externally applied tension. The

diameter of a circular hole, or width of an elongated hole, for a plug weld

should be at least 8 mm more than the thickness of the part containing it.

The ends of elongated holes either should be semicircular or should have

corners that are rounded to a radius of not less than the thickness of the part

containing the slot, except for those ends that extend to the edge of the part

concerned. The thickness of a plug weld in parent material up to 16 mm

thick should be equal to the thickness of the parent material. The thickness

of a plug weld in parent material over 16 mm thick should be at least half

the thickness of the parent material and not less than 16 mm. The center-

to-center spacing of plug welds should not exceed the value necessary to

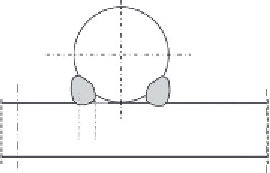

prevent local buckling. For solid bars, the design effective throat thickness

of flare groove welds, when fitted flush to the surface of the solid section of

the bars, is defined in

Figure 3.36

. In the case of welds with packing, the

packing should be trimmed flush with the edge of the part that is to be

welded. Where two parts connected by welding are separated by packing

having a thickness less than the leg length of weld necessary to transmit the

force, the required leg length should be increased by the thickness of the

packing. Where two parts connected by welding are separated by packing

having a thickness equal to, or greater than, the leg length of weld necessary

a

Figure 3.36 Effective throat thickness of flare groove welds in solid sections specified in

EC3 (BS EN 1993-1-8) [2.13].

Search WWH ::

Custom Search