Image Processing Reference

In-Depth Information

Toner master curves

Gloss (

g

)

TMA

C

+

R

(λ)

M

Color

model

Fuser temperature

Y

Reflectance

K

Fuser model

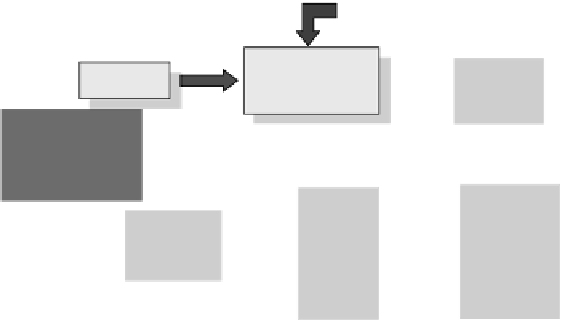

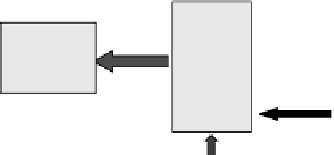

FIGURE 10.50

Effect of transferred image on the paper.

Halftoning strategy:

(Bayer, error diffusion)

Profile

selection

Input image

(

Lab

,

sRGB

)

Halftone

patch

CMYK

2-D spatial

quantizer

Q

(

x

) [0,1]

Generate

ROS profile

MTF

Laser beam

profile

(Gaussian, sinc

2

)

Intensity

profile

.icc profile

X

Toner

curves

Master

C

M

Exposure

Fuser

+

Color

model

R

(λ)

V

g

V

bias

V

a

Color space

computation

Output

image

(

Lab

,

sRGB

)

Development

Y

K

Reflectance

Transfer

Printer

actuators

: Control inputs

: Signal flow

Toner mass

transfer

(mg/cm

2

)

Fuser

temperature

Printer parameters

: Parameters

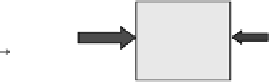

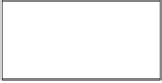

FIGURE 10.51

Image flow in the virtual printer model.

simulation, we assume that the input image is given in the L*a*b*orsRGB format.

This input image needs to be transformed to a CMYK separated image before it can

be processed by the model. For this purpose, it is necessary to develop a machine

pro

le that is an inverse mapping between L*a*b* (or XYZ) and device CMYK

values using techniques described in Chapter 7.

Figure 10.51 shows an overview of the image

flow in the printer model. The

input to the model is an electronic image in sRGB format and the output of the

model is an electronic image in the CIELab format, which can be transformed to

the sRGB format to display on the screen for evaluation purposes. The different

stages that the input image goes through are summarized as follows. We omit the

computational details like scaling of images and the resolution concerns for a later

section.

Search WWH ::

Custom Search