Environmental Engineering Reference

In-Depth Information

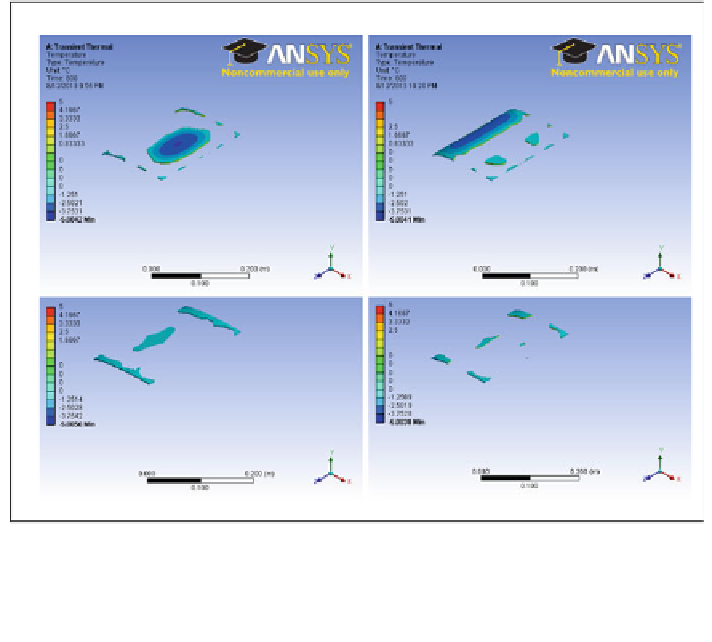

Aligned

Staggered

(a)

(b)

(c)

(d)

t = 600 sec

Fig. 8.22

Ice residue for different layouts at t = 600 s after switching on the resistors with an

q = 400 W/m

2

.

m

3

.

V

ice

¼

3

:

46

10

5

input

heat

flux

of

a

Aligned

square

layout

with

m

3

.

b

Staggered

square

layout

with

V

ice

¼

4

:

57

10

5

c

Aligned

circular

layout

with

V

ice

¼

1

:

58

10

5

m

3

. d Staggered circular layout with V

ice

¼

8

:

1

10

6

m

3

hexagonal) were investigated and it was observed that their de-icing performance

cost value J is between the performance costs of the square and circular heaters in

Table

8.2

.

Besides minimizing the total de-icing time and improving ice melting efficiency

in the leading edge area, decreasing the amount of applied thermal stress is another

important factor to be considered in the design of distributed active de-icing

systems. Our calculations show that aligned layouts induce higher thermal stress

than staggered layouts, which result in higher maximum temperatures and larger

areas with higher temperature on the blade. This observation is more subtle due to

the partial absorption of the generated heat flux in the upper surface of the blade by

the ice layer. In summary, in the case of using aligned heaters for de-icing, more

careful considerations are needed in the selection of closed-loop control gains to

avoid high thermal stress induction to the blade structure. Clearly, having reliable

and accurate on-the-blade optical sensing prevents this high thermal stress

induction by switching off those resistors near the regions where ice does not exist.