Environmental Engineering Reference

In-Depth Information

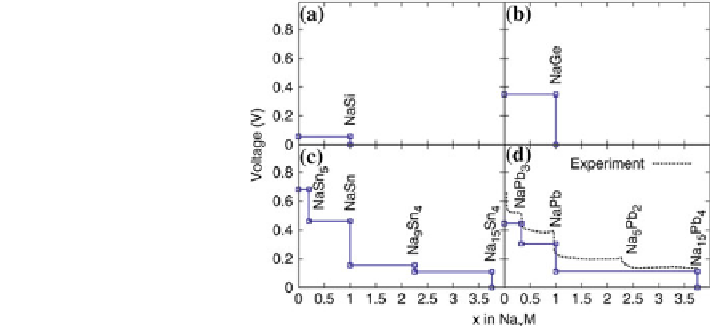

Fig. 24 Na-M voltage

curves calculated using DFT

and known Na-M crystal

structures. a M-Si b M-Ge c

M-Sn, and d M-Pb [

63

]

However, when the layer spacings increase to 0.37 nm, the energy barrier for Na-

ion insertion drops markedly to 0.053 eV, indicating a feasibility of Na-ion

insertion. Therefore, it is important to seek carbon materials with appropriate layer

spacing to improve the Na insertion performance.

4.2 Alloy Materials

As shown above, the Na storage capacity of carbonaceous materials is commonly

\300 mAh g

-1

, it is difficult to further enhance their capacity due to the limited

host sites in the carbon structure. Besides, the Na intercalation potentials in car-

bonaceous materials are close to the plating potential of Na ions, which would lead

to a safety concern. Hence, it is necessary to seek alternative anode materials for

high-capacity and high-safety Na-ion batteries. Analogous to Li alloy, Na can also

alloy with some Group IVA and VA metal elements, such as Sn, Sb, Pb, and Ge

[

62

]. These alloys are estimated to deliver high reversible capacity due to their

high theoretical-specific capacities, such as 847 (Na

15

Sn

4

), 660 (Na

3

Sb), 1108

(Na

3

Ge), and 484 (Na

15

Pb

4

) mAh g

-1

, respectively. Besides, the alloying reac-

tions have higher thermodynamic potential than Na-C reactions, making them

potentially safer. Recently, Ceder et al. reported the Na-M voltage curves cal-

culated through density functional theory (DFT) for Si, Ge, Sn, and Pb (Fig.

24

)

[

63

]. The voltage curves for Si and Ge showed only one voltage plateau, indicating

the formation of a single alloy phase. On the contrary, the voltage curves for Sn

and Pb exhibited multi-voltage plateaus, corresponding to the formation of mul-

tiple alloy phases during the Na intercalation/deintercalation. These theoretical

calculations are in good agreement with the experimental data in the literatures

[

62

,

64

-

68

] Jow et al. studied the electrochemical performance of Na

15

Pb

4

alloy

for Na intercalation [

64

]. The metallurgically formed Na

15

Pb

4

gave out 86 % of

the Na storage capacity at a low rate of 50 lAcm

-3

.

Search WWH ::

Custom Search