Agriculture Reference

In-Depth Information

THE BHOPAL INCIDENT

No case illustrates the need for green engineering principles in every design

better than the chemical accident at Bhopal, India. No designer wants to read a

newspaper account such as the following about one's project:

In the middle of the night of December 2-3, 1984, residents living

near the Union Carbide pesticide plant in Bhopal, India awoke coughing,

choking, gasping, and in the case of thousands, slowly dying. Half a day later,

half a world away, company executives sleeping soundly near the Danbury,

CT headquarters of Union Carbide Corporation awoke in the middle of

the night yawning and grumbling at the sound of telephones ringing

.

Shortcuts taken in the name of profit—authorized by the highest executives

within the company—had just killed thousands of innocent citizens. It was

the worst industrial disaster of the 20th century, forever changing the public's

trust of the chemical industry. Union Carbide claimed it was sabotage by

a disgruntled employee that led to the disaster, but how much did the

company already know about the dangerous conditions its shortcuts and

bottom-line focus had created?

5

...

Among the largest air pollution disasters of all time occurred in Bhopal, in

1984 when a toxic cloud drifted over the city from the Union Carbide pesticide

plant. This gas leak led to the death of 20,000 people and the permanent injury

of 120,000 others. We often talk about a failure that results from not applying

the sciences correctly (e.g., a mathematical, error, an incorrect extrapolation of a

physical principle). Another type of failure results from misjudgments of human

factors. Bhopal had both.

Although the Union Carbide Company was headquartered in the United

States, as of 1984 it operated in 38 countries. It was quite large (the thirty-fifth-

largest U.S. company) and was involved in numerous types of manufacturing,

most of which involved proprietary chemical processes. The pesticide manufac-

turing plant in Bhopal had produced the insecticides Sevin and Cararyl since

1969, using the intermediate product methyl isocyanate (MIC) in its gas phase.

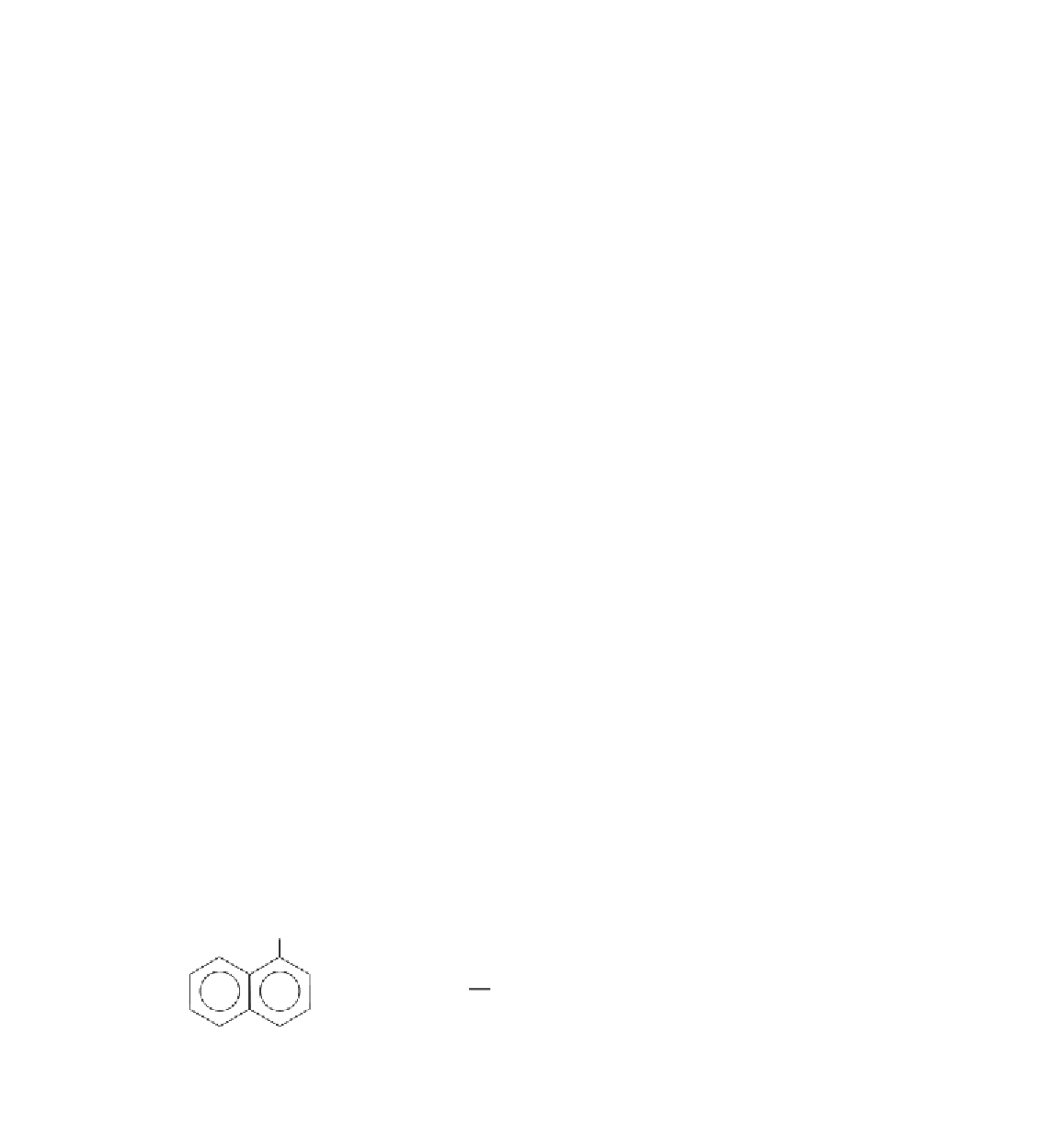

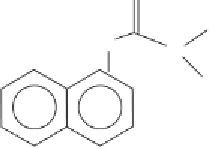

The MIC was produced by the reaction shown in Figure 3.4.

6

This process

Figure 3.4

Chemical reaction

producing methyl isocyanate at

the Bhopal, India, Union Carbide

plant.

O

CH

3

OH

O

N

H

+ CH

3

N

C

O

Search WWH ::

Custom Search