Agriculture Reference

In-Depth Information

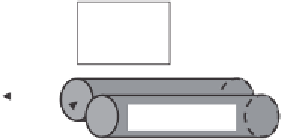

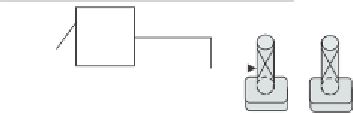

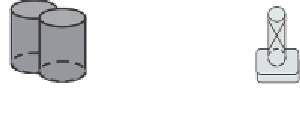

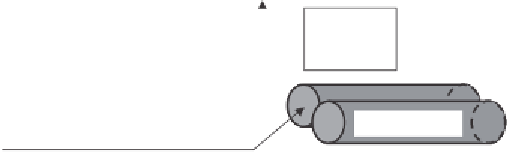

Scrubber and flare

N

2

gas

N

2

gas

Coolant out

Coolant out

Normal

vent

Normal

vent

Cooler

Cooler

Pressure

release

device

Pressure

release

device

Coolant in

Coolant in

Circulation

Circulation

To auxiliary tank

To auxiliary tank

2 pressure

monitors

2 pressure

monitors

Performance

Performance

Monitor

To process

distribution

To process

distribution

monitor

Temperature

monitor

Performance

Monitor

Performance

monitor

Ground surface

Ground surface

Cycle pump

Feed pump

2 tank

inventory

monitors

2 tank

inventory

monitors

Pressure

Monitor

Pressure

monitor

Normal vent

Normal vent

N

2

gas

N

2

gas

Pressure

release

device

Pressure

release

device

Pressure

release

device

Pressure

release

device

Emergency vent

Emergency vent

Unit

product

Unit

product

Sevin

Sevin

3 storage tanks

3 storage tanks

Methyl

carbamates

Methyl

carbamates

3 MIC unit tanks

3 MIC unit tanks

Scrubber

Scrubber

(See cutaway detail)

(See cutaway detail)

N

2

gas

N

2

gas

Normal vent

Normal vent

Normal vent

Normal vent

N

2

gas

N

2

gas

Pressure

release

device

Pressure

release

device

Pressure

release

device

Pressure

release

device

Flare

Flare

Emergency

vent

Emergency

vent

Emergency

vent

Emergency

vent

Flare

Flare

Scrubbers

Scrubbers

Scrubber

Scrubber

Methomyl unit tank

Methomyl unit tank

2 distribution tanks

2 distribution tanks

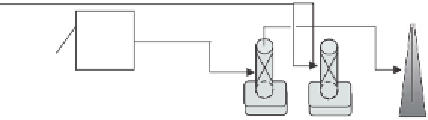

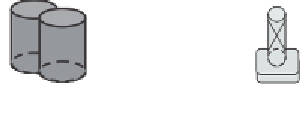

Figure 3.5

Methyl isocyanate

processes at the Bhopal, India,

plant circa 1984.

Adapted from W. Worthy, 1985,

“Methyl isocyanate: the chemistry of a

hazard,”

Chemical Engineering News

,

63(66), 29.

was highly cost-effective, involving only a single reaction step. A schematic of the

MIC process in shown in Figure 3.5. MIC is highly water reactive (see Table 3.1);

that is, it reacts violently with water, generating a very strong exothermic reaction

that produces carbon dioxide. When MIC vaporizes, it becomes a highly toxic

gas that, when concentrated, is highly caustic and burns tissues. This can lead to

scalding nasal and throat passages, blinding, and loss of limbs, as well as death.

An important point can be made about the information in Table 3.1. The

safety limits are based on workplace and workday scenarios (i.e., 8-hr days and

40-hr weeks). This is different, yet informative for residential building design.

For example, contaminant levels should be even more protective for residential

structure's indoor occupants, since they will be potentially exposed for larger

times (sometimes 24 hours per day for an entire lifetime).

Search WWH ::

Custom Search