Environmental Engineering Reference

In-Depth Information

6.0

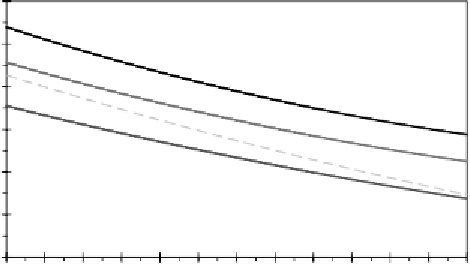

slug flow

solid curves for m

S

= 30 kg h

-1

+ m

V

/2

dashed curves m

S

= 50 kg h

-1

+ m

V

/2

5.0

4.0

m

v

= 8 kg h

-1

3.0

m

v

= 6 kg

h

-1

2.0

bubbly flow

m

v

= 4 kg h

-1

1.0

0.0

90

95

100

105

110

115

120

125

130

135

140

145

150

Mean internal generator temperature T

G

/ °C

Figure 5.53

Transition from slug to bubbly flow as a function of mean generator temperature for

different tube diameters

Asimple expression given byNarayankhedkar andMaiya (1985) relates the required

minimum height difference

Y

between the rich solution level in the reservoir and the

level of the heating zone at which the bubbles are formed in the bubble pump for

the circulation. The derivation of the minimum height difference equation with the

coefficients

K

1

and

K

2

is described in Chen

et al

., (1996). The minimum height

difference increases with the bubble pump lifting height

h

and decreases with the

mean generator boiling temperature

T

b

. The analysis is based on the assumptions that

all bubbles are formed at the bottom of the minimum height difference, that there is no

relative velocity between the weak solution and the refrigerant vapour bubbles in the

tube, and the friction loss and vapour pressure of the absorbent water are negligible:

ph

Y

=

ρ

Sr

K

1

p

K

2

10

3

(5.11)

+

−

p

where

1

−

X

Sr

K

1

=

(1

−

X

Sw

)

ρ

Sw

(

X

Sr

−

X

Sw

)

RT

b

(1

K

2

=

−

X

Sw

)

M

NH

3

For a relative molecular mass

M

NH

3

of the refrigerant ammonia of 17 kg kmol

−

1

and the given data in Table 5.6 for mean boiling temperatures, rich and weak solu-

tion concentrations and densities, total pressures and the two different lifting heights,

Search WWH ::

Custom Search