Chemistry Reference

In-Depth Information

H

O

H

O

H

H

O

H

O

H

Ligand exchange

Cation-assisted

ligand assembly

Ligand

free

Si

O

O

O

Si

O

Si

O

Si

O

O

O

Si

Si

O

O

O

Si

O

Si

OSi

Si

O

O

O

O

Silanisation

Hydrophobic-

hydrophobic

interaction

Si

Si

O

O

Si

Si

O

Si

O

O

O

O

-

Si

O

O

O

O

O

Si

O

Si

Si

O

Si

O

Ligand

oxidation

Layer-by-layer

Host-guest

interaction

α

-CD

β

-CD

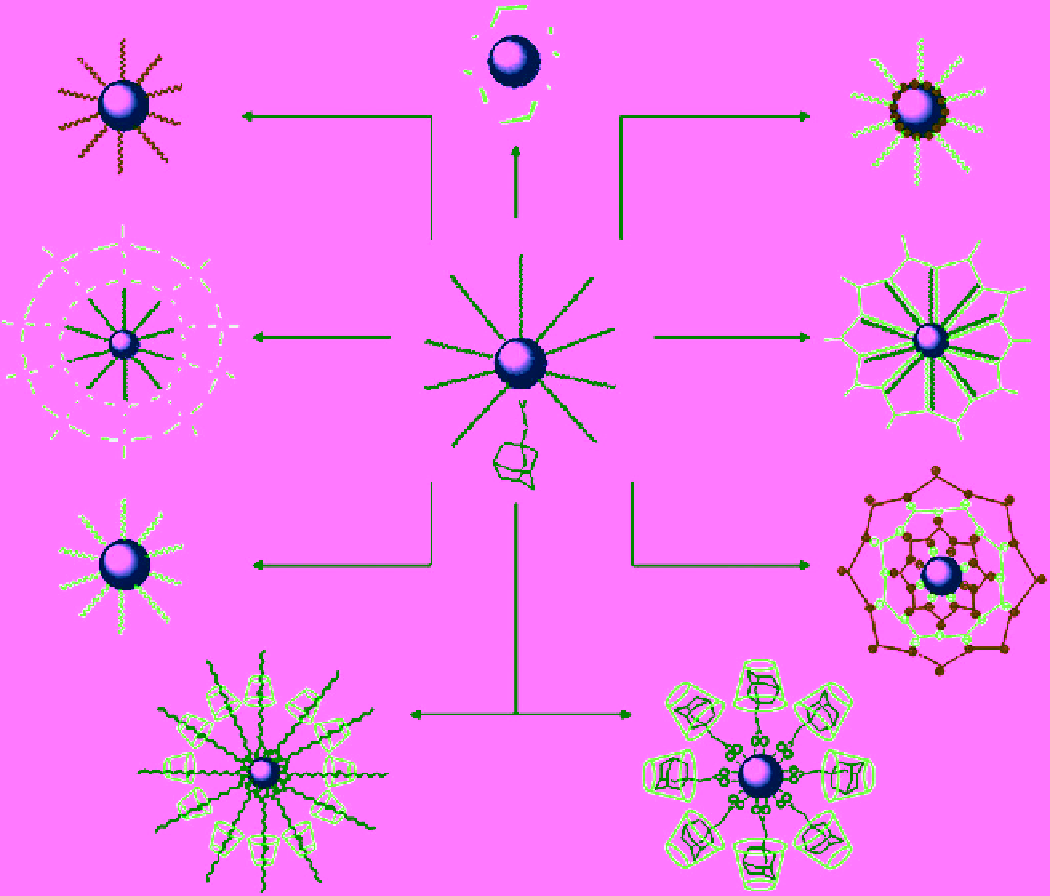

Scheme 13.2

general strategies to modify the surface properties of Ln-UCNPs [5].

groups then point outward to form a hydrophilic layer. oA-PAA-PEg [52], CTAB, anionic AoT, and nonionic PEg

tert

-octylphenyl ether [53] have been shown to serve as amphiphilic molecules to achieve this goal.

A layer-by-layer assembly method is another route to construct a hydrophilic surface. Li and co-workers have used poly-

electrolytes, such as PAH and PSS deposited on the surface of Ln-UCNPs [54]. Due to the repulsion between charges of the

same kind, only one layer of polyelectrolytes can be deposited on the Ln-UCNPs at a time. The alternate usage of negative

and positive polyelectrolytes will result in the layer-by-layer assemblies. Thus, the size of the assembled NPs can be con-

trolled accurately.

Host-guest interaction is another force to enable the effective assembly of ligands. Li and co-workers developed an

efficient method to draw oA-coated Ln-UCNPs into water by introducing

alpha

-cyclodextrin as the host to interact with

oA (guest) molecules [55]. A similar method is also used for the adamantaneacetic acid-capped Ln-UCNPs, using

beta

-

cyclodextrin instead of

alpha

-cyclodextrin.

The last but perhaps most important method is the silanisation of Ln-UCNPs. This protocol is the easiest one and gives

the best flexibility to link Ln-UCNPs with biomolecules. To date, a series of silanisation methods have been developed for

Ln-UCNPs with various surface ligands. Ln-UCNPs with hydrophilic capping ligands can be directly coated by silica via

the common Stöber method; therefore, the abovementioned products can all be coated with a silica shell after transitioning

to the hydrophilic surface [56]. The thickness of the silica shell can be controlled by the ratio of TEoS and Ln-UCNPs.

Reverse microemulsion systems can be used to obtain a silica shell outside the hydrophobic Ln-UCNPs [57]. Typically,

polyoxyethylene 5-nonylphenylether, branched (Igepal Co520) is used as a surfactant to form the microemulsion. Ln-UCNPs