Biomedical Engineering Reference

In-Depth Information

showed that using high cell densities during

inoculation of the scaffolds produced more

uniform results among experimental runs.

Scanning electron microscopy (SEM) exam-

ination showed that for both droplet and cell-

suspension samples, cells were present only at

one side of the mesh. When rotation was used,

no cell sheet was formed, and cells invaded the

meshes and grew to surround the titanium

fi bers.

a titanium fi ber mesh. After seeding, the con-

structs were cultured under static conditions or

in a fl ow-perfusion system for several days (Fig.

5

). Cell proliferation and matrix mineraliza-

tion increased in the fl ow-perfusion system.

Examination by SEM revealed that the samples

subjected to fl ow-perfusion culture were com-

pletely covered with layers of cells and mineral-

ized matrix. In addition, this matrix extended

deep into the scaffolds. In contrast, meshes

cultured under static conditions had only a

thin sheet of matrix present on the upper

surface of the meshes. Evaluation of the light

microscopy sections confi rmed the SEM obser-

vations (Fig.

.

1

5.4.2 Nutritional Conditions

Another variable affecting implant outcome is

the optimization of the nutrient conditions

and oxygen supply so that the osteogenic capac-

ity of the cultured cells is enhanced. Cell cul-

ture in three-dimensional scaffolds occurs

under completely different conditions from

those present in conventional planar two-

dimensional conditions, in which all cells are

continuously exposed to the culture medium.

An inverse relationship between proliferation

and differentiation in bone cell cultures result-

ing from a decline in the nutritional state

during mineralized matrix deposition has been

observed [

).

Subsequent studies examined the infl uence

of fl uid fl ow and fl uid shear forces on cell-

loaded titanium fi ber meshes in a fl ow-

perfusion system [

5

.

2

],

the authors used different rates of fl ow for an

extended period to permit osteoblast differen-

tiation. Histological analysis showed that an

increased fl ow rate produced a more uniform

distribution of cells and matrix mineralization

throughout the scaffold. Also, an increased

fl ow rate produced an accelerated osteoblastic

differentiation pathway. The osteoblast marker

osteopontin appeared earlier, as did the late

osteoblast

2

,

33

]. In the fi rst study [

2

].

Dynamic culturing of cells (bioreactor, rotat-

ing-wall vessel, and spinner fl ask) after seeding

of the scaffolds has been reported to have a

positive effect on cell proliferation and differ-

entiation. Furthermore, Goldstein et al. [

26

differentiation

event,

calcium

deposition.

In a second study [

], these researchers kept

the fl uid fl ow rate constant, but cultured the

cell-loaded titanium fi ber meshes in the fl ow-

perfusion system using culture media of differ-

ent viscosities. This strategy exposed cultured

33

]

demonstrated that use of fl ow-perfusion tech-

niques enhanced the early differentiation and

three-dimensional distribution of marrow

stromal cells seeded on poly(DL-lactic-co-

glycolic acid) scaffolds in comparison with

scaffolds cultured in a spinner-fl ask bioreactor,

in a rotating-vessel bioreactor, or under con-

ventional static conditions. Static cultured con-

structs exhibited uneven cell distribution and

low cellularity in the center of the constructs,

with most cells growing near the periphery of

the construct. In contrast, constructs cultured

under dynamic conditions showed higher cel-

lularity and a more uniform distribution of

cells throughout the constructs. Interestingly,

the production of extracellular matrix (ECM)

was increased when a dynamic culture method

replaced a static method.

Van den Dolder et al. [

10

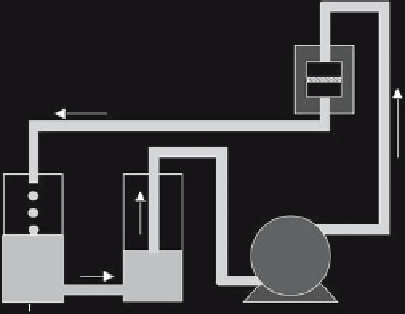

Flow Chamber

with Scaffold

Pump

] investigated the

effect of a dynamic culture method on cell pro-

liferation and differentiation from a seeded cell

suspension of rat bone marrow stromal cells in

36

Media

Reservoirs

Figure 5.1.

Schematic figure of the flow-perfusion system.