Biomedical Engineering Reference

In-Depth Information

of tissue as a function of oxygen transport to

and from the cells within that volume, the

boundary condition, i.e., the fl u x of ox ygen into

the tissue from surrounding tissues, needs to be

specifi ed. If, on the other hand, the presence of

injury or disease causes the control volume to

become disconnected functionally from its sur-

rounding tissue, then a sealed boundary con-

dition with a constant zero or low fl ux may be

more appropriate. The mass balance of oxygen

within the model will be signifi cantly affected

by which boundary condition is chosen. In the

studies at hand, we defi ned a stiffness and

permeability of the material at all edges (bound-

aries). To model a long bone (Fig

Interestingly, it was shown that variation in

periosteal permeability exerts the greatest

infl uence on pore pressure distribution, which

drives fl ow within the cortex (Fig.

). This

was particularly surprising, given that the

periosteum is often assumed to be a “sealed

surface” in modeling bone as a poroelastic

material. [

10

.

7

].

Four-point bending loads were applied to the

model (Fig.

12

,

26

D), with the loading conditions

the same as those applied in vivo. Using the

equations of poroelasticity [

10

.

6

] embedded in the

fi nite element program, we calculated pressure

gradients that are shown in Fig.

4

10

.

6

E. Each

), we defi ned

the endosteum, i.e., the boundary between the

cortex and the medullary cavity, as material

that exhibits low stiffness but high permeabil-

ity. This defi nition refl ects the high degree

of vascularization and permeability of the

endosteum, but does not signifi cantly refl ect

the structural strength of bone. In contrast, the

bone cortex contributes signifi cantly to the

structural strength and stiffness of bone, but is

less permeable than the soft endosteal tissue,

because it is made up of relatively impermeable

mineralized matrix. Finally, the periosteum

or outer surface of the bone was assumed to

exhibit both low stiffness and permeability. A

parametric study was carried out to determine

the degree of infl uence that each of these vari-

ables has on the fl ow fi eld within the bone cortex.

10

.

7

cross section of the tibia (in Fig.

E) was then

depicted with one aspect under compression

and one under tension, with the neutral axis in

between (Fig.

10

.

6

F).

We then calculated mass transport with the

aid of the heat transfer package of the fi nite

element software. Mass and heat transport are

governed by the same equations, provided

inertial terms can be neglected, as here. This

calculation led to the magnitudes (Fig.

10

.

6

A)

and directions for every velocity vector at every

element in the model. We had expected that

fl uid would be squeezed out of segments under

compression and taken up by segments under

tension. This was not the case in our original

model (Fig.

10

.

9

B) and led us to examine criti-

cally the defi nition of the material parameters

in the new model (see below). To calculate mass

10

.

9

60

1E-14

50

1E-13

40

1E-12

30

1E-11

20

1E-10

10

1E-9

0

1E-8

-10

Endosteum

Open

0

10

20

30

40

periosteum

endosteum

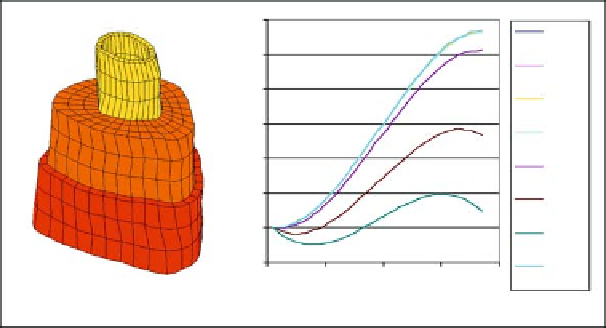

Figure 10.7.

Effect of boundary conditions on the development of pore pressure in the cortex. The finite element mesh is divided

into three concentric sections to define independently material properties of the endosteum (yellow, sheath closest to the medul-

lary cavity, low stiffness and high permeability), the cortex (orange, high stiffness and medium permeability), and the periosteum

(red, outer sheath, low stiffness, permeability varied). The pore pressure (kPa, y-axis) in the cortex between the surface closest to

the endosteum and periosteum, respectively, is plotted as a function of periosteal sheath permeability (colored lines represent

permeability, as defined in the sidebar). Reprinted from Journal of Theoretical Biology, Volume 220, R. Steck, P. Niederer, and

M.L. Knothe Tate, “A finite element analysis for the prediction of load-induced fluid flow and mechanochemical transduction in

bone,” p. 252, with permission from Elsevier.