Environmental Engineering Reference

In-Depth Information

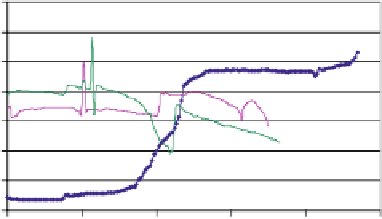

standards, presence of fructose, citric acid, lactic acid, acetic acid, and butyric acid

was detected. In addition, a few other peaks were observed, which were not charac-

terized due to lack of appropriate standards. It was found that the anode biocatalyst

growth was slow using the wastewater as the sole nutrient source. The biocata-

lyst was therefore established using a defined nutrient medium containing glucose

and lactate at 0.2 g/L, each. After the biocatalyst was established, as indicated by

a current of 1 mA at a load of 250

(Fig. 5.2), the MFC was exposed to the

wastewater. The biocatalyst was first acclimated to 25% wastewater, mixed with

the nutrient medium (without amended carbon source), followed by operation with

100%wastewater. A current of 2.1 mA was obtained at a load of 100

with the 25%

wastewater stream. A similar current was obtained with the full strength wastewater

as well. However, the current rapidly dropped below 1 mA. The decrease in current

was due to a drop in pH. The wastewater was not ammended with any buffer salts

which was the primary reason for the drop in pH to below 6.0, within the two day

period. Adjustment of the pH to 7.0 reinstated the current output (Fig. 5.2). Thus,

pH control would be necessary for the MFC application. The MFC produced elec-

tricity continuously from 200 mL of wastewater for a period of 7 days at above 400

mW/m

2

power density (37 W/m

3

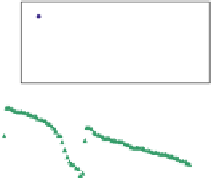

of total anode volume). A power density analysis

indicated a maximum of 470 mW/m

2

(Fig. 5.3). Operation of the MFC for three

additional days increased the power density to 690 mW/m

2

(54 W/m

3

). No further

increase in the power density was observed over the next month. An analysis of the

internal resistances of the MFC via electrochemical impedance spectroscopy (EIS)

indicated that the ohmic resistance was less than 10 ohms.

Typical power densities obtained using food industry wastewater as the energy

source have been in the range of 80-370 mW/m

2

[25, 39] (see further discussion

below). The power density obtained in this study is relatively higher than those

reported in literature. The primary reason for this is the MFC architecture which

lowers the internal resistance of the MFC as indicated by the low ohmic resistance

observed for this design. Further work on the assessment of the impedances via EIS

is in progess and will be reported elsewhere.

Biocatalyst growth

25% wastewater

100% wastewater

0.35

0.3

0.25

0.2

Fig. 5.2

Voltage output

during biocatalyst growth and

during use of wastewater as

the fuel source. The load on

the MFC was 250 and 100

0.15

0.1

0.05

during the growth period and

the wastewater testing period,

respectively

0

0

1

2

3

4

5

Time, days