Environmental Engineering Reference

In-Depth Information

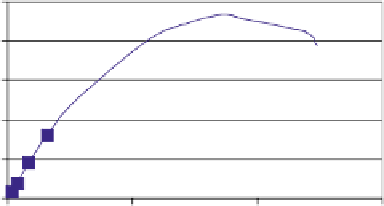

500

Fig. 5.3

Power density of the

MFC using dairy wastewater

as the energy source

400

300

200

100

0

0.0

2.0

4.0

6.0

mA

5.3.4 Complex Organic Matter in Dairy Processing Wastewater

The Mayfield wastewater potentially contained complex organic carbon in the form

of dissolved as well as suspended particulate matter. The HPLC analysis indicated

a total of about 0.5 g/L dissolved solids in the wastewater. This amount of organic

carbon would provide continuous power for a period of 8 days, assuming 100%

coulombic efficiency and a current output of 2.1 mA. This is based on a total volume

of 230 mL (maximum volume of MFC system, including the reservoir). The BOD of

the wastewater was approximately 2.25 g/L (equivalent to 2.12 g/L carbohydrate).

Thus, about 1.62 g/L of the carbohydrate-equivalent organic matter was present in

a complex organic form.

5.3.5 Assessment of MFC/MEC Application for Food Industry

Wastewater Treatment

In application of bioelectrochemical systems for treatment of food processing

wastewaters, a number of factors need detailed assessment, especially if the goal

is to maximize energy generation. In the following subsections, we review and dis-

cuss energy production from complex organic matter, potential changes to improve

power densities and pursue practical applications and potential for water reuse in

the industry.

5.3.5.1 Deriving Energy from Complex Organic Matter

Electricity production from starch, molasses, cellulose, protein and other complex

carbon sources has been reported using MFCs [14, 39, 41-44]. Deriving energy

from the complex, soluble as well as suspended organic matter in food processing

waters therefore should be possible, but further work is required to demonstrate the

degree of conversion of these wastewater constituents. The suspended particulates

may require modified MFC designs to handle solids or pretreatment to solubilize