Environmental Engineering Reference

In-Depth Information

taBle 11.7

Willow Biomass cropping system management and harvest schedule

year

season

activity

0

Fall

Mow, contact herbicide, plow, disk, seed covercrop, cultipack

1

Spring

Disk, cultipack, plant, pre-emergent herbicide, mechanical and/or

herbicide weed control

1

Winter

First year coppice

2

Spring

Fertilize

3

Spring

4

Winter

First harvest

5

Spring

Fertilize

6

Spring

7

Winter

Second harvest

(8-22)

(Repeat 3-year cycle for 3rd-7th harvest)

23

Spring/summer

Elimination of willow stools

Source:

Keoleian, G.A. and Volk, T.A.,

Crit Plant Sci Rev

, 24, 385-406, 2005.

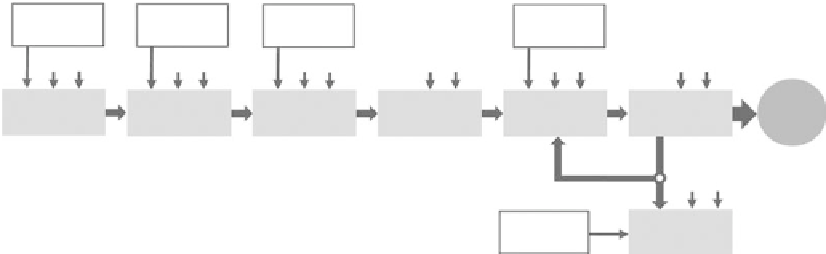

Herbicide

production

Nursery

operations

Herbicide

production

Fertilizer

production

DM

DM

DM

DM

DM

DM

Field

preparation

Weed

control

Willow

biomass

Planting

Coppice

Fertilize

Harvest

7 3-year

rotations

D = diesel fuel production

M = farm machinery manufacturing

DM

Herbicide

production

Willow stool

elimination

FIGure 11.20

Willow biomass production agriculture model. (From Keoleian, G.A. and Volk, T.A.,

Crit

Plant Sci Rev

, 24, 385-406, 2005.)

Keoleian and Volk (2005), building on previous work (Heller et al. 2003, 2004), provided a com-

prehensive assessment of the energy, GHG, air pollutant, land requirements, and economic impacts

of a willow biomass-to-electricity conversion system in New York state. Herein, the focus is placed

on the system's life-cycle energy balance.

The base case agriculture scenario in Keoleian and Volk (2005) followed the schedule described

in Table 11.7. Willow biomass yields were expected to increase 30-40% by later harvests, but wil-

low plants devote significant amounts of energy to establishing their roots in their first few years.

The willow biomass was assumed to contain 50% moisture by dry weight at harvest. Combustion

of this biomass would subsequently cause the power plant's efficiency to slightly decrease. The

agricultural model is outlined in Figure 11.20.

Combined biomass and coal combustion at a power plant (i.e., co-firing) was examined for two

90% coal/10% biomass scenarios, in addition to a baseline 100% coal input scenario. Co-firing

above 2% requires power plant modification; the impacts of these material requirements were

included in this study (retrofit material production in Figure 11.21). Manufacture of the original

power plant equipment was excluded because prior studies have shown it affects system life-

cycle indicators by less than 1% (Spath et al. 1999). The biomass-to-electricity system model is

outlined Figure 11.21. The functional unit in this analysis was 1 MWh of electricity delivered

to the grid.